There were two sets of Tips, onshore and offshore, corresponding with the two markets Vulcan sold and serviced its products into. The Vulcan Offshore Tips have been on this site and its predecessors since 1998; it is appropriate that these appeared on the tenth anniversary of that posting. In the case where the specific onshore tip has an offshore counterpart, we’ve linked to the offshore tip. In cases where we’ve covered the same information in other ways, we’ve linked to that too.

Many tips refer to factory parts and service. Obviously these are no longer available, but there are sources for most of what is contained in these tips.

As is the case with the offshore tips, we’ve added commentary where appropriate. We also strongly recommend that you acquire the Vulcan Hammer Guide to Pile Driving Equipment for more information and several field service manuals for Vulcan hammers. Some of the tips are covered in that volume and are linked appropriately.

TIP # 001 : HEAD GASKET/SINGLE ACTING HAMMER

We have noticed over the years that some hammer users do not replace a leaking Cylinder Head Gasket on Single Acting Hammers. They do this on the assumption that it really isn't necessary because a Single Acting Hammer does not have pressure between...

Read More

Tip #001: HEAD GASKET/SINGLE ACTING HAMMER

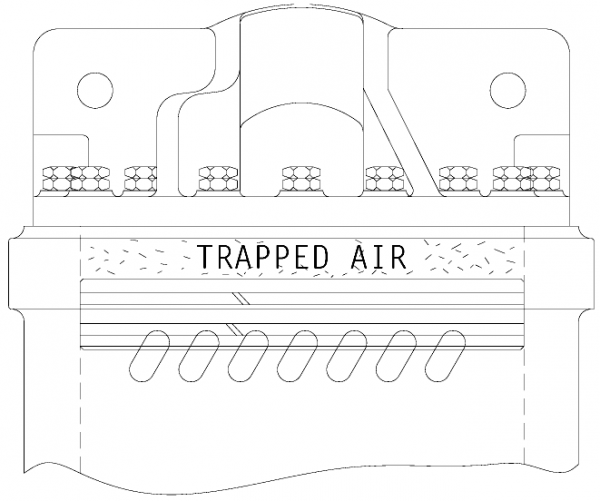

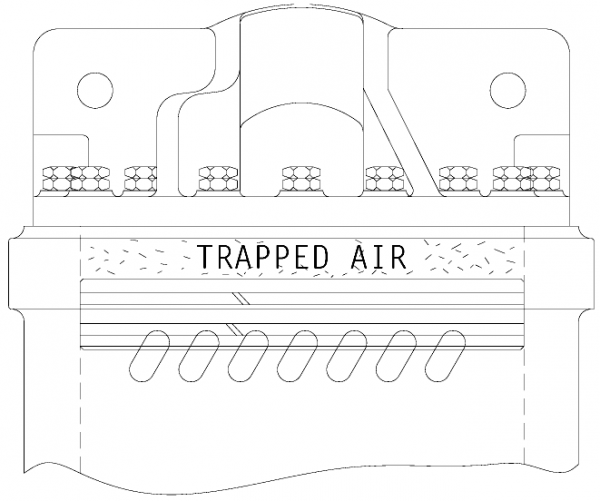

We have noticed over the years that some hammer users do not replace a leaking Cylinder Head Gasket on Single Acting Hammers. They do this on the assumption that it really isn’t necessary because a Single Acting Hammer does not have pressure between the Cylinder Head and the Piston. It is true that on Single Acting Hammers air or steam is not directed into this area as is done on Differential Hammers. But when the Piston of a Single Acting Hammer Is on the upstroke the Piston travels up past the Exhaust Ports and traps air between the Cylinder Head and the Piston. This trapped air acts as a cushion to slow up and stop the upward travel of the Piston and Ram. Without the Cylinder Head Gasket the trapped air will escape and the Piston will strike the Cylinder Heed. Eventually this pounding will lengthen or strip the threads of the Cylinder Head Studs. This will allow more air to escape until the Piston will strike the Cylinder Head on every stroke and will break the Cylinder Studs and tear the Cylinder Head completely from the Hammer.

We have noticed over the years that some hammer users do not replace a leaking Cylinder Head Gasket on Single Acting Hammers. They do this on the assumption that it really isn’t necessary because a Single Acting Hammer does not have pressure between the Cylinder Head and the Piston. It is true that on Single Acting Hammers air or steam is not directed into this area as is done on Differential Hammers. But when the Piston of a Single Acting Hammer Is on the upstroke the Piston travels up past the Exhaust Ports and traps air between the Cylinder Head and the Piston. This trapped air acts as a cushion to slow up and stop the upward travel of the Piston and Ram. Without the Cylinder Head Gasket the trapped air will escape and the Piston will strike the Cylinder Heed. Eventually this pounding will lengthen or strip the threads of the Cylinder Head Studs. This will allow more air to escape until the Piston will strike the Cylinder Head on every stroke and will break the Cylinder Studs and tear the Cylinder Head completely from the Hammer.

TIP # 002 : CHECKING SLIDE BAR

A quick way to check the correct position of the slide bar is shown in the drawing and picture above. Place a straightedge across the machined boss area of the Ram as shown in the picture. The lower edge of the straightedge should be even with the...

Read More

Tip #002: CHECKING SLIDE BAR

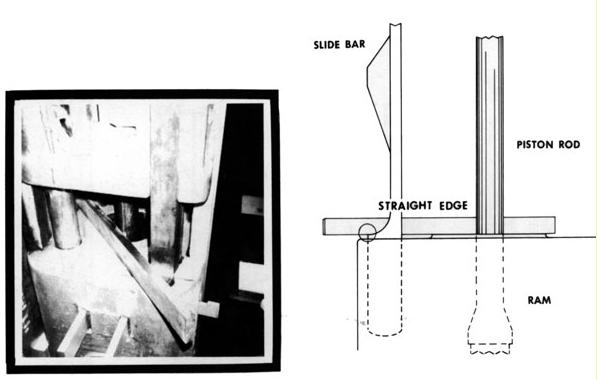

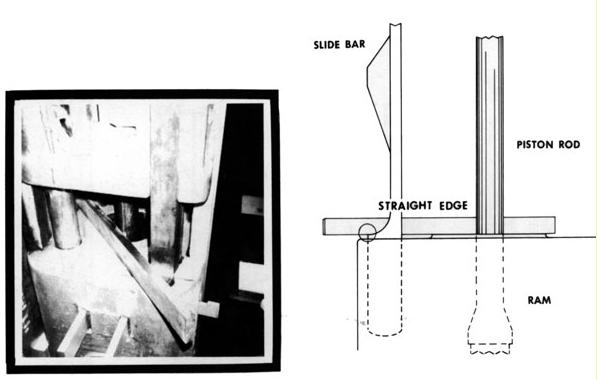

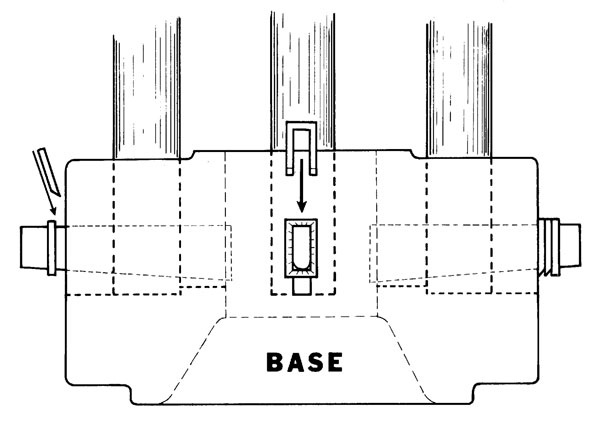

A quick way to check the correct position of the slide bar is shown in the drawing and picture above.

A quick way to check the correct position of the slide bar is shown in the drawing and picture above.

Place a straightedge across the machined boss area of the Ram as shown in the picture. The lower edge of the straightedge should be even with the “break” of the round stock of the slide bar as circled in the drawing.

Note: strictly speaking, this only applied to hammers of the “020” series or smaller. Hammers larger than this have a gap between the straight edge and the slide bar break. Details on this are available in the Vulcanhammer Guide to Pile Driving Equipment.

TIP # 003 : VALVE FLUTTER

Under certain atmospheric conditions, a film of ice will form on the inside wall of the steam chest. This film prevents the valve from seating properly and also reduces friction between the valve and steam chest wall. In some driving conditions, this...

Read More

Tip #003: VALVE FLUTTER

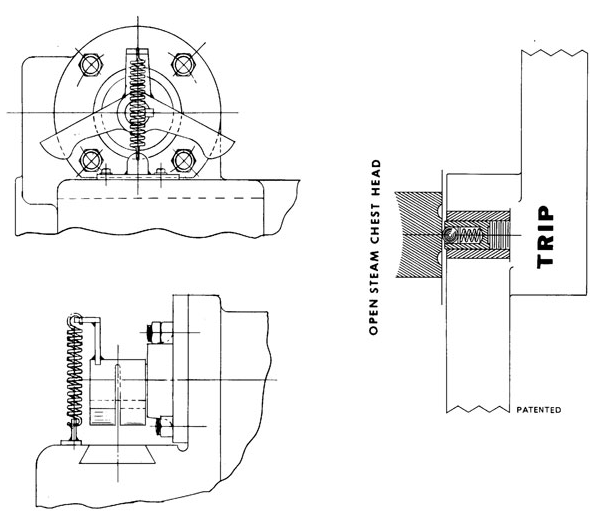

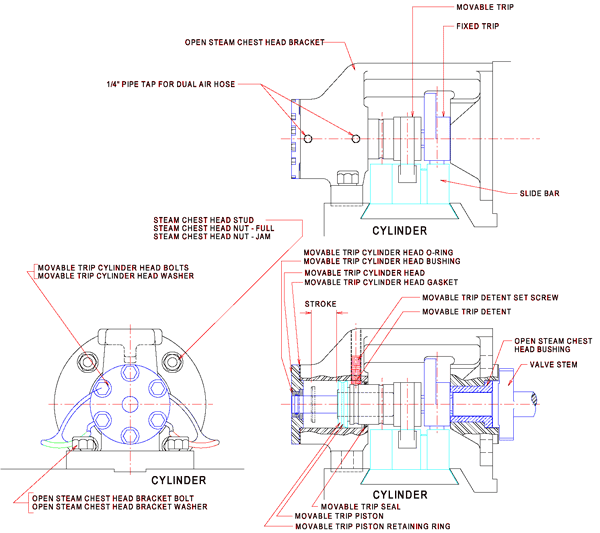

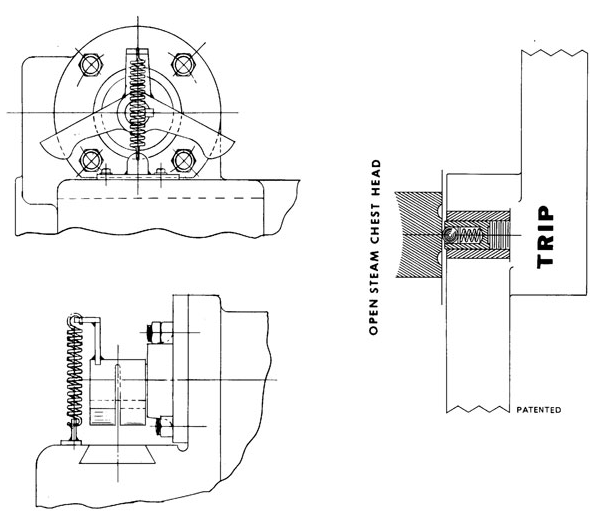

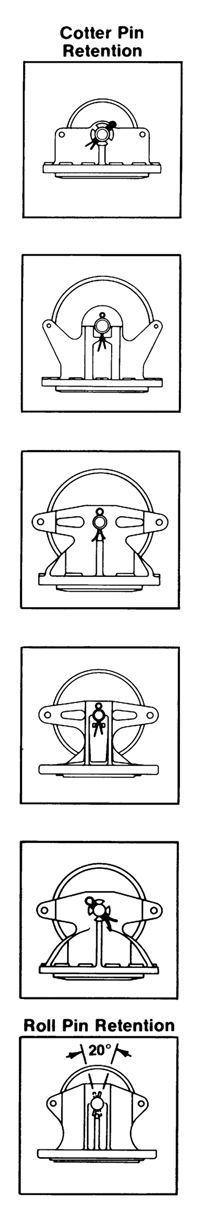

Under certain atmospheric conditions, a film of ice will form on the inside wall of the steam chest. This film prevents the valve from seating properly and also reduces friction between the valve and steam chest wall. In some driving conditions, this lack of friction will allow the valve to “bounce” or “flutter,” needless to say, causing poor performance of the hammer. A quick remedy is the spring arrangement shown in the drawings above left. The spring holds the trip over center as it rotates. A permanent solution to flutter is shown in the drawing above right. This drawing is of the new type trip and open steam chest head equipped with a detent spring.

Under certain atmospheric conditions, a film of ice will form on the inside wall of the steam chest. This film prevents the valve from seating properly and also reduces friction between the valve and steam chest wall. In some driving conditions, this lack of friction will allow the valve to “bounce” or “flutter,” needless to say, causing poor performance of the hammer. A quick remedy is the spring arrangement shown in the drawings above left. The spring holds the trip over center as it rotates. A permanent solution to flutter is shown in the drawing above right. This drawing is of the new type trip and open steam chest head equipped with a detent spring.

TIP # 004 : REDUCED HAMMER ENERGY

Vulcan Hammer Guide to Pile Driving Equipment...

Read More

TIP # 005 : LUBRICATION

Below are the lubrication specifications for the Vulcan offshore pile hammers. Below is a hammer diagram showing the locations of lubricant applications. APPLICATION POINT Lube Type Oil Viscosity Flash Point (Min.) Other Requirements...

Read More

Tip #005: LUBRICATION

Below are the lubrication specifications for the Vulcan offshore pile hammers. Below is a hammer diagram showing the locations of lubricant applications.

APPLICATION POINT

|

Lube Type

|

Oil Viscosity

|

Flash Point (Min.)

|

Other Requirements

|

SUS, 212° F

|

cSt, 100°C

|

Deg. F

|

Deg. C

|

- Cylinder and Base Jaws.

- Trip Faces.

- Slide Bar.

- Slide Bar Dovetail.

- Columns/Ram Grease fittings

- Columns/Exposed Surfaces

- Hydra/Nuts

|

NLGI EP2 Grease

|

70-100

|

13-20

|

450

|

235

|

- Permitted Thickners

- Lithium 12 Hydroxy-Stearate

- Lithium Complex

- Calcium Complex

- Polyurea

- MoS2 Anti-Wear Additive

- Anti-Rust Additive

|

- Relief Ports (Steam Opr.)

- Steam Line Oiler

|

Steam Cylinder Oil

AGMA 8

|

160-190

|

34-41

|

550

|

290

|

10% Tallow or Lard Content

|

- Relief Ports (Air Opr.)

- Air Line Oiler

|

Air Compressor Oil

AGMA 1

|

40-50

|

40-50

|

400

|

200

|

Anti-Oxidant

|

- Outboard Bearing

- Open Steam Chest Bearing

|

Gear Oil

AGMA 5 EP

|

80-105

|

80-105

|

400

|

200

|

|

Image: Lubrication diagram

It is important to keep your Vulcan hammer properly lubricated to insure the maximum possible hammer life and driving performance.

Also, for the threads of the cable fittings. use an an anti-seize compound to prevent galIing and freezing of the threads.

*NLGI EP2 greases will vary widely in the results for this application. Another alternative to this is a heavy open gear lubricant with MoS2 anti-wear additive. This should be applied directly to the exposed columns.

TIP # 006 : KEEPING RAM KEYS TIGHT

When some hammers get enough mileage on them to warrant retirement and under certain driving conditions, the contractor may have trouble keeping the ram keys tight. Usually under these circumstances, the contractor will weld the keys to the ram and...

Read More

Tip #006: KEEPING RAM KEYS TIGHT

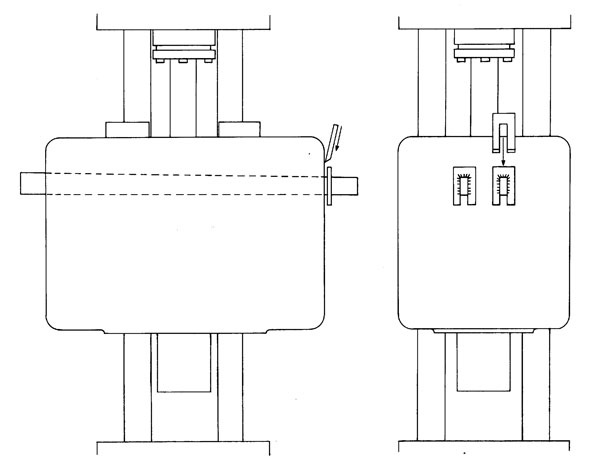

When some hammers get enough mileage on them to warrant retirement and under certain driving conditions, the contractor may have trouble keeping the ram keys tight. Usually under these circumstances, the contractor will weld the keys to the ram and worry about the consequences later. The drawing above shows a better way of keeping the keys tight and allows for quick and easy re-tightening during the job.

When some hammers get enough mileage on them to warrant retirement and under certain driving conditions, the contractor may have trouble keeping the ram keys tight. Usually under these circumstances, the contractor will weld the keys to the ram and worry about the consequences later. The drawing above shows a better way of keeping the keys tight and allows for quick and easy re-tightening during the job.

TIP # 007 : 11 RULES FOR PILE DRIVING

The Name of the Game -- Heavier Ram - Shorter Stroke Concrete piles cracking while driving in either soft silt or very hard ground? The solution is the same for both problems: Use a thicker cushion block and a hammer with a heavier ram and shorter...

Read More

Tip #007: 11 RULES FOR PILE DRIVING

The Name of the Game — Heavier Ram – Shorter Stroke

Concrete piles cracking while driving in either soft silt or very hard ground? The solution is the same for both problems: Use a thicker cushion block and a hammer with a heavier ram and shorter stroke. The solution and others to related problems, comes from Prof. T. J. Hirsch of Texas A&M’s Texas Transportation Institute, who led a research project in the problems of cracking and spalling concrete piles. TTI is the official research agency for the state highway department. His reasoning is this: The compression wave sent down a pile by the hammer blow. rebounds back up the pile when it reaches the end – as a tension wave if the pile tip is in a soft medium that offers little resistance, and as a compression wave if the pile tip is lodged against something very firm. If the pile is long and the stress waves short, the return wave will meet the compression wave of the next hammer blow, and the two can add up to a resultant force that is destructive. A heavier ram has a longer impact time on the head of the pile. and thus produces a longer compression wave. Thicker cushioning also stretches out the impact time. Professor Hirsch sums up the fundamentals of good pile design and pile driving as follows:

- Use adequate cushioning materials between the pile driver’s steel helmet or cap and the concrete pile head. For piles under 50 ft., only 3 or 4 in. of wood cushioning material (such a green oak, gum. pine, or fir wood plywood) may be adequate if there is reasonably good point soil resistance. More wood cushioning, 6 to 8 in. or more, may be required when driving longer piles in very soft soil. The wood cushioning material should be placed on top of the pile with the grain horizontal and inspected to see that it is in good condition. When it begins to become highly compressed, charred, or burned, it should be replaced. Some specifications require a new cushion on every pile. If driving is extremely hard, the cushion may have to be replaced several times during driving of a single pile. Adequate cushioning is usually a very economical way to control driving stresses.

- Driving stresses can be reduced by using a heavy ram with a low impact velocity (short stroke) to obtain the desired driving energy rather than a light ram with a high impact velocity (large stroke). Driving stresses are proportional to the ram impact velocity.

- Reduce the ram velocity or stroke during early driving when light soil resistance is encountered. Anticipate soft driving, or at the first sign of easy driving reduce the ram velocity or stroke to avoid critical tensile stresses. This is very effective when driving long piles through very soft soil.

- If predrilling or jetting is permitted in placing the piles, be sure that the pile point is well seated with reasonable resistance at the point before full driving energy is used. Driving and jetting should not be done simultaneously.

- Be sure that the pile driving helmet or cap fits loosely around pile top so that the pile may rotate slightly without binding within the driving head to prevent torsional stress. The helmet should be centered on pile head so eccentric load will not be applied.

- The pile should be straight and not cambered because of uneven prestress or poor concrete placement during casting. High flexural stresses may result during driving of a crooked pile.

- The top of the pile must be square or perpendicular to the longitudinal axis of the pile. Eccentricity concentrates stress.

- Cut the ends of prestressing or reinforcing steel flush with the end of the pile head to prevent their direct loading by the ram stroke.

- Use adequate spiral rdnforcing at the pile head and tip to reduce the tendency of the pile to split or spall.

- Use adequate amount of prestress in prestressed piles or reinforcement in ordinary precast piles to resist reflected tensile stresses.

- Chamfer the top and bottom edges and corners of the pile to reduce the tendency of the concrete to spall.

Originally appeared in Hirsch, T.J. (1966) Construction Methods and Equipment, New York: McGraw-Hill.

The whole subject of “heavy mass-low striking velocity” is one that Vulcan dealt with throughout the entire history of the air/steam hammer line. The debate has survived the company: one competitor took space in his first online newsletter to make the following commentary on this very tip:

That was written in 1966. At the time, the air hammer was a popular tool. Then the diesel hammer took over the world, and the mighty air hammer manufacturers are a tiny fraction of what they were.

While there’s no doubt diesel hammers have been successful, the physics that Dr. Hirsch describes are still correct, but must be understood in proper context.

When steam hammers were first introduced, one of the major changes that took place was the relationship between ram weight and hammer energy. Drop hammers were inherently long-stroke hammers, and the pile top damage to the wood piles could be considerable. Shortening the stroke and increasing the ram weight reduced the peak force in the pile, and thus the driving stresses in the pile. This became more critical when concrete piles became popular, as controlling the tension cracking phenomenon Hirsch describes is critical.

Diesel hammers, to some extent, reversed the trend by reducing the ram weight and lengthening the stroke. This made for a lighter hammer, and one that didn’t require the external power source. So how to control the pile stresses? One way is to decrease the cushion stiffness, which decreases the natural frequency and increases the impact period. To some extent, the effect of shortening the stroke can be replicated in this way, but not entirely.

It’s also noteworthy that steel piling are more resistant to driving stresses. So high velocity impact is not as critical with these piles as it is with concrete piles. Vulcan recognized this fact in the development of the 560, first produced around the time this tip was issued.

However, for the driving of concrete piles, especially larger size and capacity piles, it’s still best to use a hammer with a low impact velocity and a heavy ram to limit the pile stresses, be that hammer an air/steam or hydraulic hammer.

TIP # 008 : RAM KEYS TOO TIGHT

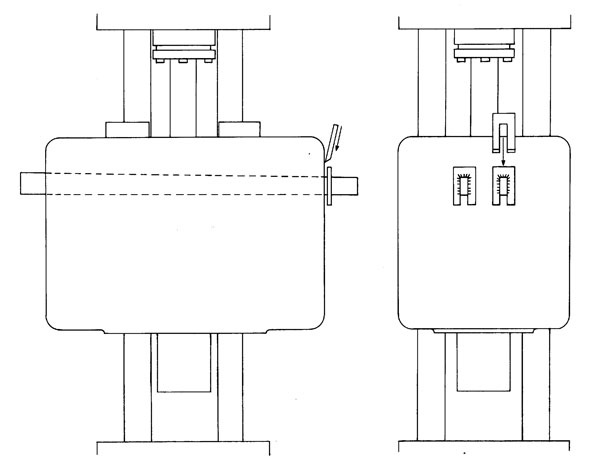

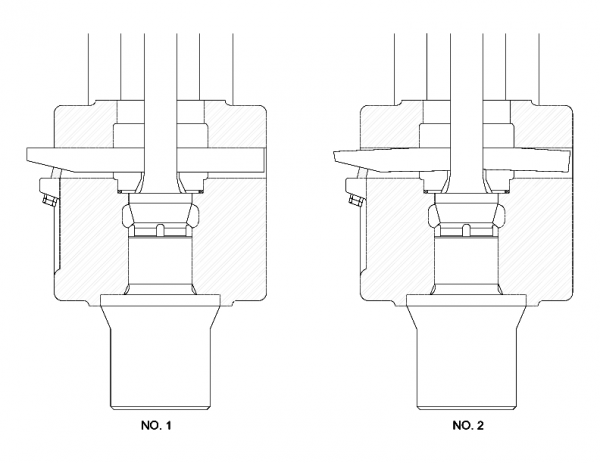

Sometimes it is difficult not to tighten the Ram Keys too much. Driven with a heavy weight a Ram Key can easily be driven so far as to bend. Figure No.1 shows a Ram Key properly seated. Figure No.2 shows a Ram Key driven too far and bent. The key is...

Read More

Tip #008: RAM KEYS TOO TIGHT

Sometimes it is difficult not to tighten the Ram Keys too much. Driven with a heavy weight a Ram Key can easily be driven so far as to bend. Figure No.1 shows a Ram Key properly seated. Figure No.2 shows a Ram Key driven too far and bent. The key is tight when it just starts to leave the seat at either end.

Sometimes it is difficult not to tighten the Ram Keys too much. Driven with a heavy weight a Ram Key can easily be driven so far as to bend. Figure No.1 shows a Ram Key properly seated. Figure No.2 shows a Ram Key driven too far and bent. The key is tight when it just starts to leave the seat at either end.

TIP # 009 : BLOW COUNT/ENERGY

One of the most frequent phone calls we receive is from contractors and engineers asking "Is a Hammer delivering full energy if the blow count per minute is less than listed in the Specifications?" Blow count does not indicate full or less than full...

Read More

Tip #009: BLOW COUNT/ENERGY

One of the most frequent phone calls we receive is from contractors and engineers asking “Is a Hammer delivering full energy if the blow count per minute is less than listed in the Specifications?” Blow count does not indicate full or less than full energy.

A Single Acting Hammer will deliver full energy if the stroke is as listed in the Specifications. The length of the stroke is the only criteria of a Single Acting Hammer delivering full energy.

A Super Vulcan Differential Hammer derives some of its energy on the down stroke from the air or steam pressure. A Super Vulcan Hammer in proper condition will deliver full energy if the P.S.I. at the Hammer is as listed in the Specifications. The striking energy of a Differential Hammer will vary directly with the steam or air pressure.

The blow count (not the energy) of any Hammer will be effected by the amount of Pile set on each blow, type of cushion material, the amount of cushion material. Too little cushion material will cause the Hammer to over stroke.

In Specifications published before 1972, blow count was listed as “blows per minute at normal stroke and no set”. This means, if the P.S.I. at the Hammer is as listed in the Specifications, the Hammer is functioning properly and the Pile is at refusal.

Differential Hammers

| SIZE |

30C |

50C |

65C |

80C |

85C |

100C |

140C |

200C |

400C |

600C |

| P.S.I. |

120 |

120 |

150 |

120 |

128 |

140 |

140 |

142 |

150 |

150 |

Single-Acting Hammers

| SIZE |

2 |

1 |

06 |

08 |

0R |

010 |

014 |

016 |

020 |

030 |

040 |

| P.S.I. |

80 |

80 |

100 |

83 |

105 |

105 |

110 |

120 |

120 |

150 |

120 |

| STROKE |

2.42′ |

3 |

3.25 |

3 |

TIP # 010 : TIGHTENING THE PACKING GLAND

Many Pile Hammer mechanics have a tendency to tighten the Packing Gland too tight. A little steam or air leaking through the Packing is not objectionable. The oil mixed with the escaping air or steam will lubricate the Packing and Piston Rod...

Read More

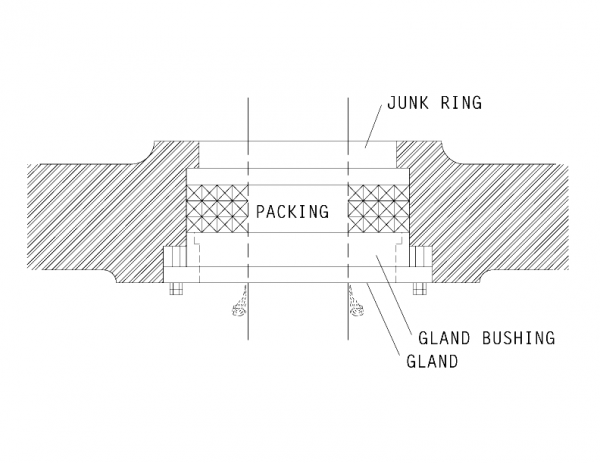

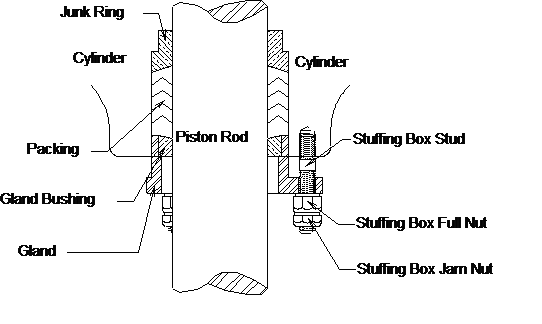

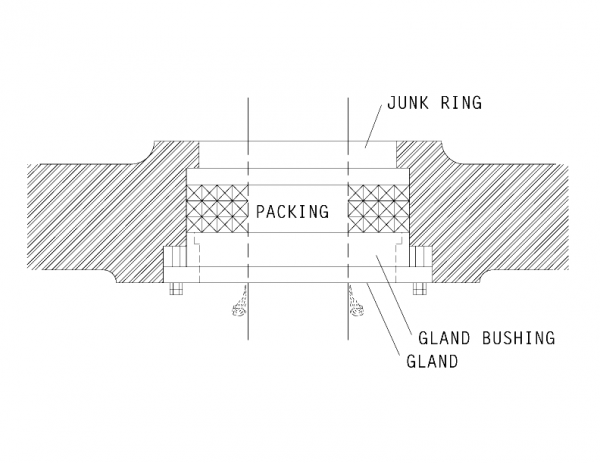

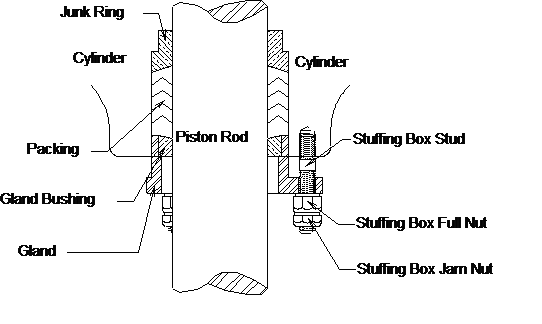

Tip #010: TIGHTENING THE PACKING GLAND

Many Pile Hammer mechanics have a tendency to tighten the Packing Gland too tight. A little steam or air leaking through the Packing is not objectionable. The oil mixed with the escaping air or steam will lubricate the Packing and Piston Rod.

Many Pile Hammer mechanics have a tendency to tighten the Packing Gland too tight. A little steam or air leaking through the Packing is not objectionable. The oil mixed with the escaping air or steam will lubricate the Packing and Piston Rod.

TIP # 011 : STORAGE

Sometimes contractors forget that a Pile Driving Hammer is a machine and should be treated as such. Especially when the Hammer is to be stored for any length of time. Rust can create havoc in a Hammer. Sometimes the contractor takes a Hammer off of...

Read More

Tip #011: TIGHTENING THE PACKING GLAND

Sometimes contractors forget that a Pile Driving Hammer is a machine and should be treated as such. Especially when the Hammer is to be stored for any length of time. Rust can create havoc in a Hammer. Sometimes the contractor takes a Hammer off of a job and lays it down in the yard expecting that it will go out on another job the next day. But two years later the Hammer is still in the same spot and rusty. Following the steps below will take about 30 minutes and save the contractor many hours of down time and expense.

- To protect the columns and piston rod rod from rust during storage,wrap them with cloth, tie with wire and soak with oil. Grease on the columns and piston rod can be washed off with a heavy rain.

- Wrap the slide bar as above.

- Stuff oil soaked rags into the exhaust port in the valve chest.

- Pour a quart of oil in the air intake and seal with water proof tape.

- On the Single Acting Hammer pour a quart of oil into the exhaust port at the top of the cylinder and seal with waterproof tape.

- On the Differential Acting Hammer stuff oil soaked rags into the lower cylinder around the piston rod.

TIP # 012 : TROUBLE SHOOTING

A. Hammer Runs Too Slow: Possible Causes: Steam Or air pressure too low. Steam supply line too long or not proper size. Steam supply line restricted in some manner. Lack of lubrication. Worn or broken piston rings or scored cyl...

Read More

Tip #012: Trouble Shooting

A. Hammer Runs Too Slow:

Possible Causes:

- Steam Or air pressure too low.

- Steam supply line too long or not proper size.

- Steam supply line restricted in some manner.

- Lack of lubrication.

- Worn or broken piston rings or scored cylinder wall. Check this by allowing enough steam to enter the cylinder to hold the ram in about a half-raised position and note whether excessive steam is blowing out of exhaust ports at top of cylinder.

- Piston rod packing gland too tight.

- Excessive steam or air leakage. Blown gaskets or packing.

- Badly worn slide bar wedges or dovetail, or bent trip.

B. Hammer Runs Too Fast

Possible Causes:

- Excessive steam or air pressure on hard driving indicated by bouncing of hammer on up stroke.

- Ram not making full stroke.

C. Excessive Slide Bar Breakage

Possible Causes:

- Slide bar key loose.

- Worn dovetail.

D. Hammer Changes Speeds While Operating:

Possible Causes:

- Boiler or compressor not large enough.

- Boiler feed water allowed to drop too low.

- Loose or torn hose lining.

- Intermittent lubrication caused by defective or empty line lubricator.

- Loose slide bar or badly won dovetail.

E. Hammer Leaks Steam at Main Exhaust Port Constantly:

Possible Causes:

- Valve not seating properly.

- Scored or broken steam chest liner.

F. Hammer leaks Steam or Air Excessively From Exhaust at Top of Cylinder:

Possible Causes:

- Worn or broken piston rings.

- Scored cylinder wall.

G. Ram Hangs and Hammer Stops Operating:

Possible Causes:

- Loose tie cables.

- Rust or burrs on column.

- Piston rings too large and seized up in cylinder.

- Piston packing too tight.

- Bent columns.

Note: Both the Onshore and Offshore Field Service Manuals have troubleshooting guides. These can be found in the Vulcan Hammer Guide to Pile Driving Equipment.

TIP # 013 : ADAPTION OF MCDERMID BASE

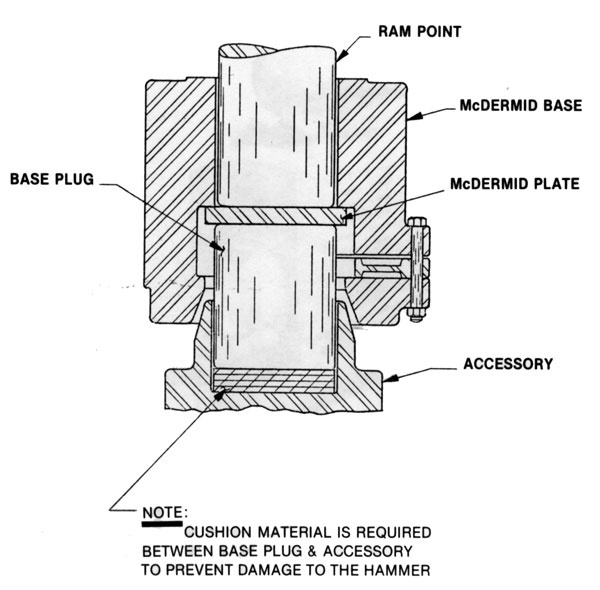

We do not recommend the use of McDermid base for any type of pile other than wood. But on occasion, contractors have found themselves in a position whom they have had to adapt a McDermid base to standard Driving Heads or Pipe Caps. The above shows...

Read More

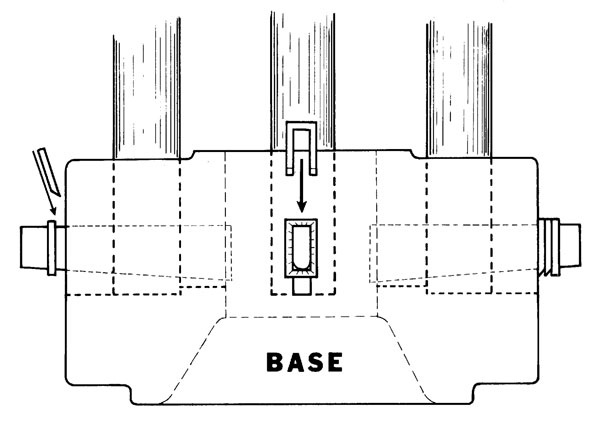

Tip #013: ADAPTION OF MCDERMID BASE

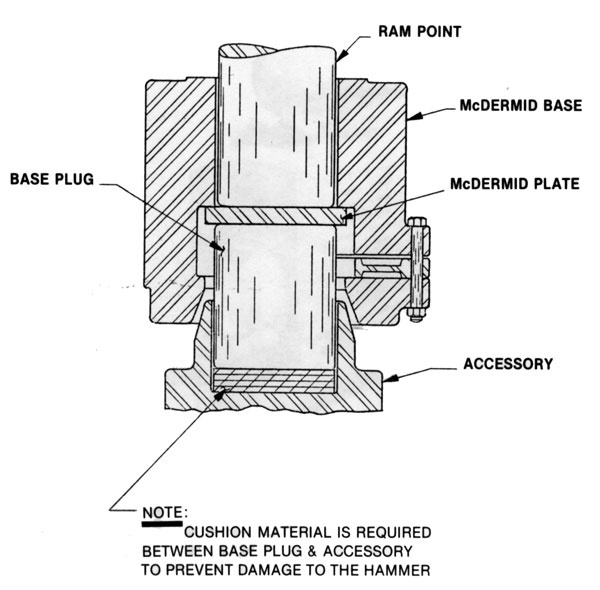

We do not recommend the use of McDermid base for any type of pile other than wood. But on occasion, contractors have found themselves in a position whom they have had to adapt a McDermid base to standard Driving Heads or Pipe Caps. The above shows the arrangement necessary to accomplish this.

We do not recommend the use of McDermid base for any type of pile other than wood. But on occasion, contractors have found themselves in a position whom they have had to adapt a McDermid base to standard Driving Heads or Pipe Caps. The above shows the arrangement necessary to accomplish this.

Note: the McDermid Base was one of the first “customisations” applied to a Vulcan hammer. Vulcan licensed this from its inventor, Hugh McDermid. Although the conical cone on Vulcan bases was originally designed to mate with tapered wood pile heads, the McDermid Base gave better alignment. This is one of the few instances where a Vulcan hammer could drive the pile “directly,” i.e., without cushion material. Unfortunately hammers equipped with a McDermid Base could only drive wood piles, thus without adaptations such as this such a hammer was limited in its scope.

Vulcan #2 equipped with a McDermid Base being set up for a demonstration driving to be included in an episode of the History Channel.

Vulcan #2 equipped with a McDermid Base being set up for a demonstration driving to be included in an episode of the History Channel.

TIP # 014 : VULCAN EXTRACTORS

The Vulcan Pile Extractor was the last major design by James N. Warrington (U.S. Patent 1,736,104) to enter production, which it did in 1928. The extractor uses a simple, valveless design where the ram is thrown upward by the incoming steam or air...

Read More

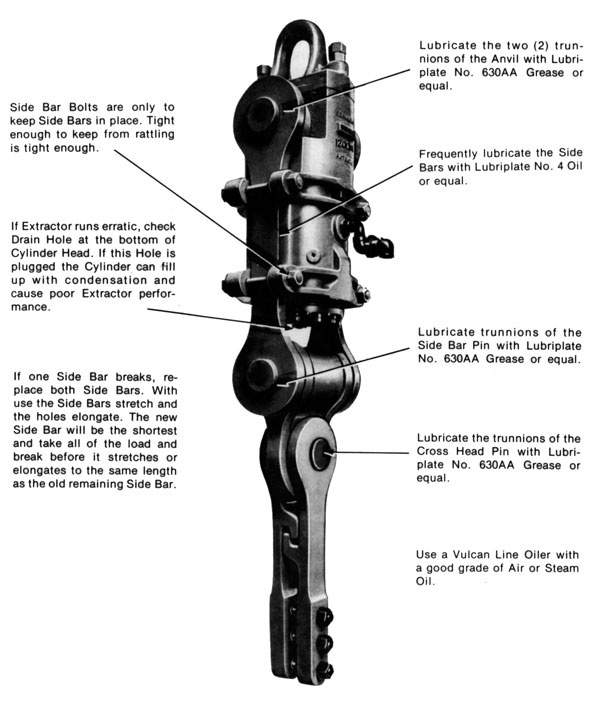

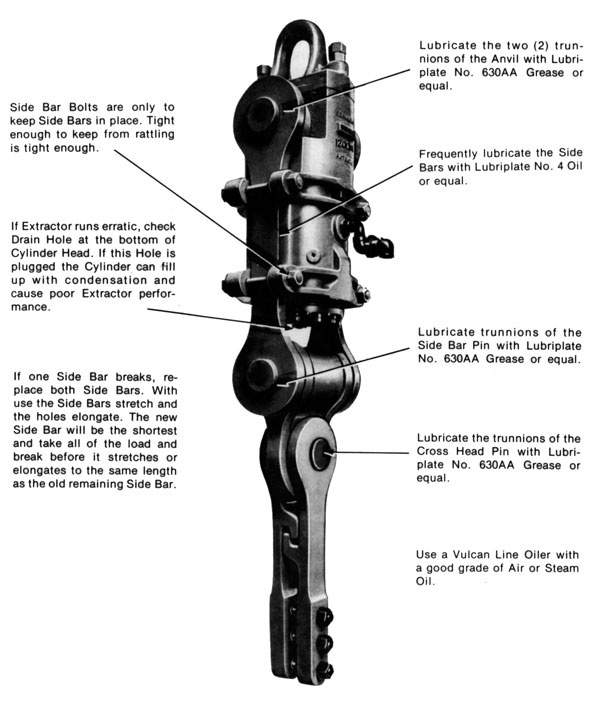

Tip #014: VULCAN EXTRACTORS

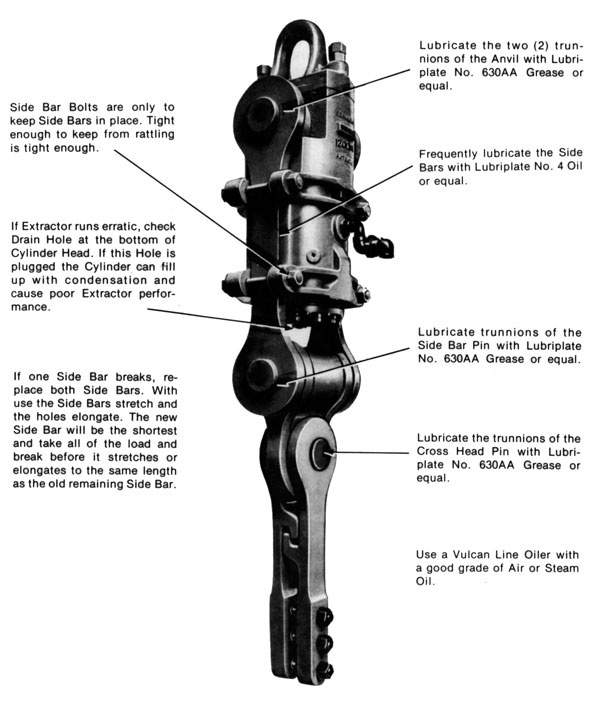

The Vulcan Pile Extractor was the last major design by James N. Warrington (U.S. Patent 1,736,104) to enter production, which it did in 1928.

The Vulcan Pile Extractor was the last major design by James N. Warrington (U.S. Patent 1,736,104) to enter production, which it did in 1928.

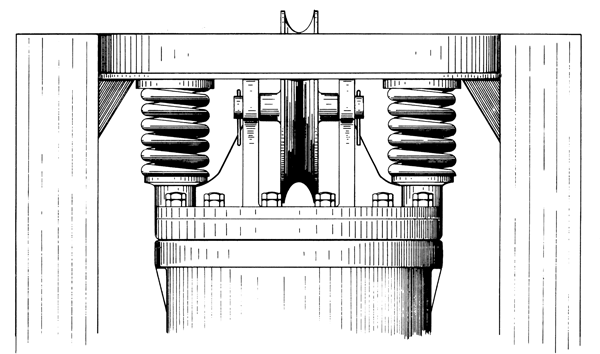

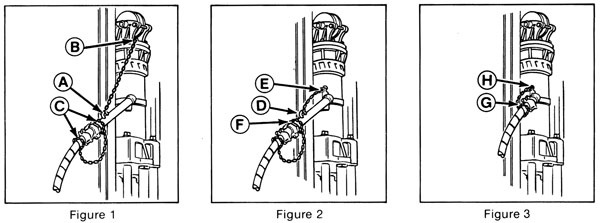

The extractor uses a simple, valveless design where the ram is thrown upward by the incoming steam or air. It strikes an anvil located in the top of the machine. The impact force is transmitted through the side bars to the cross pin and onward to the connecting links.

Although it could in principle be used to extract any pile, Vulcan pile extractors were primarily used with sheet piling, as this type of piling is very common in temporary works. An example of this is shown at the right. The main method of connecting the extractor with the piles was through the two bolts that passed through the connecting links and the corresponding holes in the sheet piling, which the sheet pile supplier would commonly drill or burn in the sheeting.

In some cases the holes could be avoided by the use of Heppenstal tongs, which are similar in principle to the grips seen on impact-vibration hammers. Vulcan also developed and patented its own pile grips as well.

Vulcan’s main competitor was the MKT “E” series, which were very similar in construction. In the 1960’s Vulcan also marketed the Nilens series of extractors, which featured a cable wrap system for transmitting the impact along with a Heppenstal type grip.

Impact extractors represented the best way of removing sheet piles until the 1970’s, when the vibratory drivers took over the job. However, for smaller jobs where there were few sheets, or jobs where the sheets were embedded in very hard soil or the interlocks rusted or beaten together, the impact extractor remains a useful tool for removing sheet piles after their job is done.

TIP # 015 : BASE COLUMN KEYS

Loose Column Keys can shorten the life of a Hammer considerably. When the Base Keys are loose the Hammer is subject to misalignment and breakage. Loose Keys will slip into the center of the Base and be struck by the Ram Point, breaking the Base. The...

Read More

Tip #015: VULCAN EXTRACTORS

The Vulcan Pile Extractor was the last major design by James N. Warrington (U.S. Patent 1,736,104) to enter production, which it did in 1928.

The Vulcan Pile Extractor was the last major design by James N. Warrington (U.S. Patent 1,736,104) to enter production, which it did in 1928.

The extractor uses a simple, valveless design where the ram is thrown upward by the incoming steam or air. It strikes an anvil located in the top of the machine. The impact force is transmitted through the side bars to the cross pin and onward to the connecting links.

Although it could in principle be used to extract any pile, Vulcan pile extractors were primarily used with sheet piling, as this type of piling is very common in temporary works. An example of this is shown at the right. The main method of connecting the extractor with the piles was through the two bolts that passed through the connecting links and the corresponding holes in the sheet piling, which the sheet pile supplier would commonly drill or burn in the sheeting.

In some cases the holes could be avoided by the use of Heppenstal tongs, which are similar in principle to the grips seen on impact-vibration hammers. Vulcan also developed and patented its own pile grips as well.

Vulcan’s main competitor was the MKT “E” series, which were very similar in construction. In the 1960’s Vulcan also marketed the Nilens series of extractors, which featured a cable wrap system for transmitting the impact along with a Heppenstal type grip.

Impact extractors represented the best way of removing sheet piles until the 1970’s, when the vibratory drivers took over the job. However, for smaller jobs where there were few sheets, or jobs where the sheets were embedded in very hard soil or the interlocks rusted or beaten together, the impact extractor remains a useful tool for removing sheet piles after their job is done.

TIP # 016 : PIPING DO’S AND DON’TS

The length of the Nipple from the Inlet must be kept to a minimum. A long Nipple, as shown in the drawing, even though supported by chain or wire rope, will cause damaging leverage and vibration. Extensions to the side, like the arrangement in the ...

Read More

Tip #016: BASE COLUMN KEYS

Loose Column Keys can shorten the life of a Hammer considerably. When the Base Keys are loose the Hammer is subject to misalignment and breakage. Loose Keys will slip into the center of the Base and be struck by the Ram Point, breaking the Base.

Loose Column Keys can shorten the life of a Hammer considerably. When the Base Keys are loose the Hammer is subject to misalignment and breakage. Loose Keys will slip into the center of the Base and be struck by the Ram Point, breaking the Base.

The drawing shows a quick and easy way to keep these keys tight and to retighten as the job progresses.

Weld the Ring to the Keys as shown. Then when the Key needs to be tightened, drive a “U” shaped washer between the Ring and Base. Drive as many washers as necessary to keep the Key tight. Then tack weld the washers to the Ring or Key, not the Base.

TIP # 017 : EXHAUST MUFFLERS

One thing most people notice first about pile driving jobs is that they generate an elevated level of noise. Until the 1960's, most people simply put up with this and many other aspects of industrialization and development. In the early 1970's, Vulca...

Read More

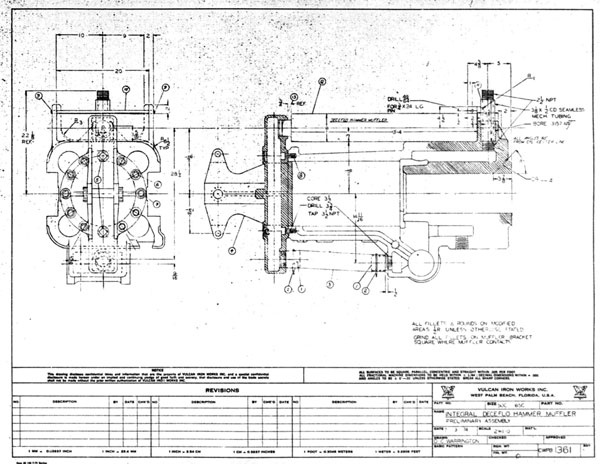

Tip #017: EXHAUST MUFFLERS

One thing most people notice first about pile driving jobs is that they generate an elevated level of noise. Until the 1960’s, most people simply put up with this and many other aspects of industrialization and development. In the early 1970’s, Vulcan and other pile driving equipment manufacturers were confronted with new regulations–both at the federal and local level–which sought to regulate the noise output of construction equipment. Needless to say, pile driving equipment was high on the list.

One thing most people notice first about pile driving jobs is that they generate an elevated level of noise. Until the 1960’s, most people simply put up with this and many other aspects of industrialization and development. In the early 1970’s, Vulcan and other pile driving equipment manufacturers were confronted with new regulations–both at the federal and local level–which sought to regulate the noise output of construction equipment. Needless to say, pile driving equipment was high on the list.

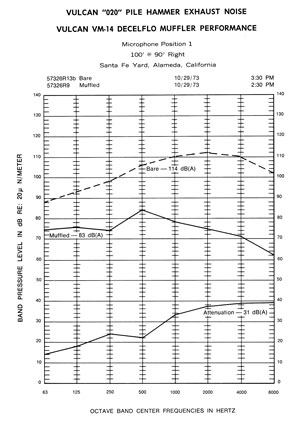

Vulcan’s first reaction was to study the issue. It retained the services of United Acoustical Consultants in Glastonbury, CT, and its principal, Stannard Potter, to study the nature of noise output of Vulcan hammers. In December 1972 they conducted a study of a Vulcan #1 at the Chattanooga facility.

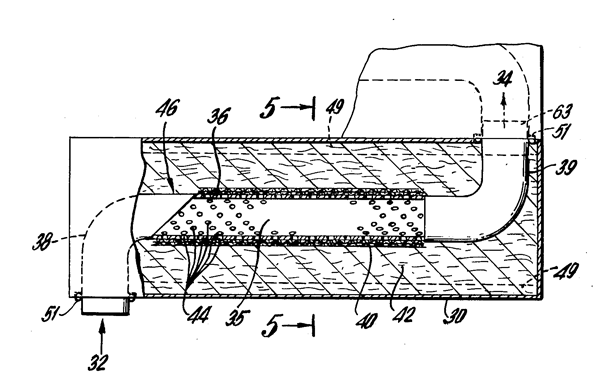

Vulcan hammers, although durable and simple, suffered from two specific difficulties for noise abatement: a) their open construction gave little natural noise attenuation, and b) their lack of a recoil dampener increased the impact load on the frame, thus making it difficult to attach shrouds and other devices to attenuate sound. However, one of the results of the study was that a large proportion of the sound emission from an operating Vulcan hammer came from the exhaust. Since muffling the exhaust was simpler than doing same with the impact, Vulcan commissioned Potter to design an exhaust muffler, which it called the Decelfo Muffler.

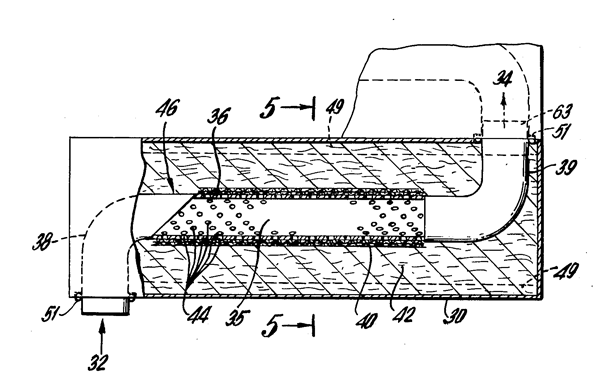

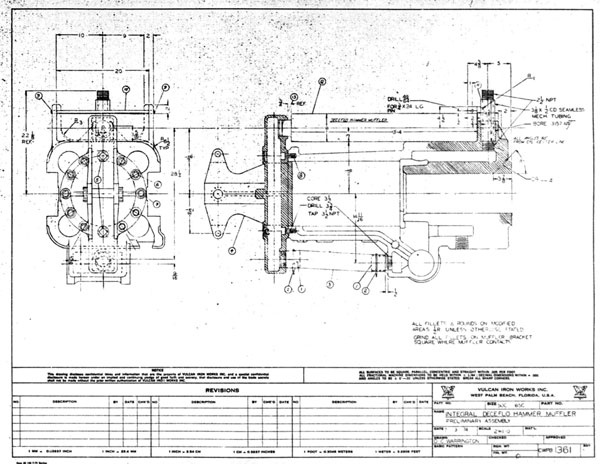

The muffer was simple, a box which directed the air or steam output of the exhaust through perforated pipe surrounded by acoustical foam. The drawing shows a stacked arrangement for the muffler, but Vulcan never employed this arrangement.

The muffer was simple, a box which directed the air or steam output of the exhaust through perforated pipe surrounded by acoustical foam. The drawing shows a stacked arrangement for the muffler, but Vulcan never employed this arrangement.

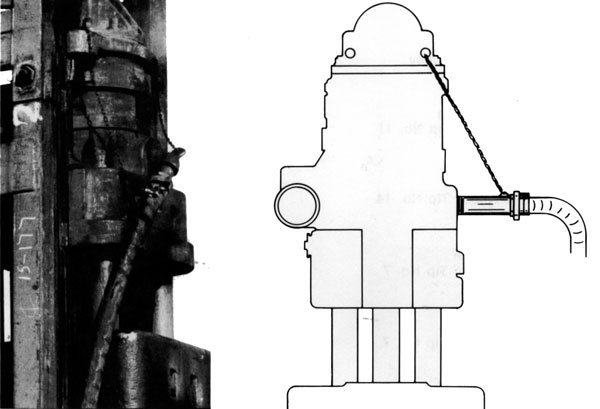

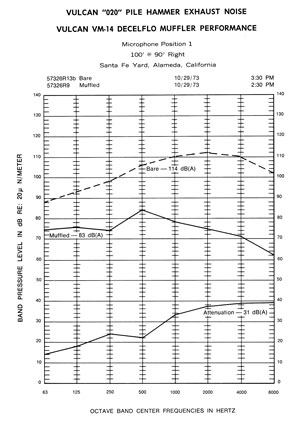

The first test of the Decelflo took place in October 1973 in the Alameda yard of Santa Fe construction in Alameda, California. It involved muffling a Vulcan 020 hammer.

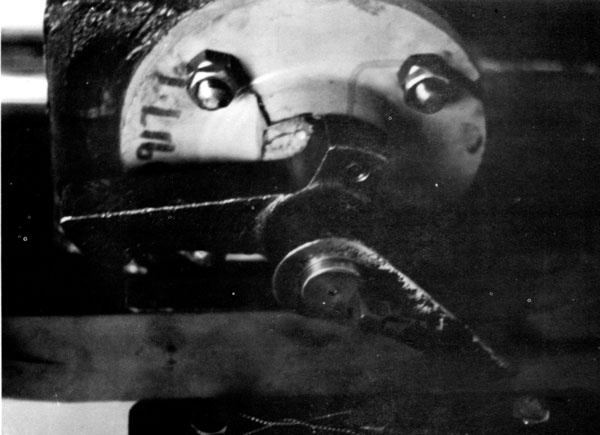

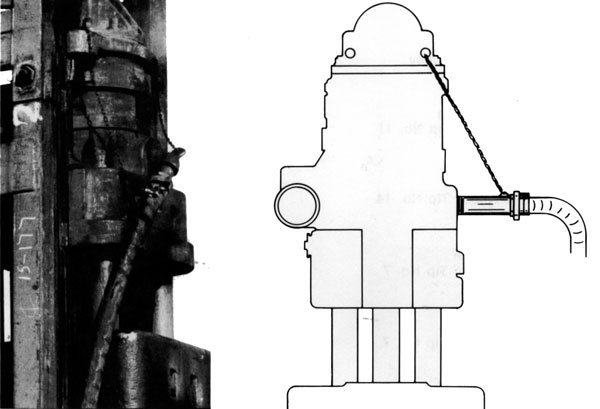

Right: setting up for the test. The muffler (the silver device at the top of the photo) is mounted on the hammer through the sheave pin, which principally is the centre shaft for the sheave wheels used to raise and lower the hammers. The bearings for the sheave pin on the muffler were connected to the muffer through rubber shock absorbers. The hammer’s exhaust was connected to the muffler using hose.

In front of the hammer Stan Potter (right) reviews the test procedure. At the left is Henry G. Warrington, Chairman of the Board and President.

As shown below, the test was successful; the muffler performed as anticipated and its used resulted in reduction of hammer noise.

Flush with this success, Vulcan continued in its development of the muffler. In July 1974 it had another opportunity to demonstrate (and verify) the Decelflo’s capabilities, this time in Chicago at a sheet piling project. Below: the Decelflo mounted on top of the Vulcan hammer, in this case a 50C. The hose connection from the exhaust port to the muffler can be clearly seen, along with its connection to the hammer via the sheave pin.

Flush with this success, Vulcan continued in its development of the muffler. In July 1974 it had another opportunity to demonstrate (and verify) the Decelflo’s capabilities, this time in Chicago at a sheet piling project. Below: the Decelflo mounted on top of the Vulcan hammer, in this case a 50C. The hose connection from the exhaust port to the muffler can be clearly seen, along with its connection to the hammer via the sheave pin.

Vulcan had great plans for the Decelflo; at this time it was working on a method to mount the muffler directly on the hammer, as shown below. But then things took a strange twist.

To begin with, there was considerable contractor resistance to the concept of having to add another device to the hammer assembly. Mounting it above the hammer lengthened the leaders required to operate the hammer, and the large installed base of Vulcan hammers dictated that this would be the normal way the muffler would be mounted.

To begin with, there was considerable contractor resistance to the concept of having to add another device to the hammer assembly. Mounting it above the hammer lengthened the leaders required to operate the hammer, and the large installed base of Vulcan hammers dictated that this would be the normal way the muffler would be mounted.

Beyond that, the level of noise emissions, and how people perceive them, vary widely from one jobsite to another. This variation is a function of the location of the job (urban, remote, etc.), the presence or absence of neighbouring buildings to reflect the sound, and whatever ambient noise is in proximity to the jobsite. For example, driving piling next to an existing interstate, with the road noise already present, may not be very perceptible.

Finally, as far as those working on the jobsite are concerned, contractors (and OSHA) found it simpler to deal with noise emissions from pile drivers and other equipment on site by providing hearing protection to the workers, which of course is standard on jobsites today.

Finally, as far as those working on the jobsite are concerned, contractors (and OSHA) found it simpler to deal with noise emissions from pile drivers and other equipment on site by providing hearing protection to the workers, which of course is standard on jobsites today.

In any case, the Decelflo muffler was never very popular, “noise pollution” never achieved the notoriety of air and water pollution, and both Vulcan and its customer base moved on to other concerns. For his part Stan Potter moved on to patent the Decelflo concept independently of Vulcan.

Thruflo (Geothermal) Muffer

The need to attenuate noise combined with another concern of the era, the need for alternative energy resources, with the geothermal muffer. An experimental product, it nevertheless touched on issues that are still important today.

Geothermal energy is possible when the hot magma which exists in the earth is close enough to the surface and the underground water to turn the latter into steam, which can be used to drive the turbines and generators to produce electric power. The means that the source of geothermal energy is not only free economically, but also that carbon dioxide (greenhouse gas) is not emitted in the production of electricity.

In the course of producing energy, the steam is vented to the atmosphere, and unmuffled this can produce a high noise level.

Below: the target for the geothermal muffer: The Geysers, a power generation plant north of San Francisco, CA, in February 1974.

Vulcan built a prototype and tested it in its own facility in August 1974.

Below: the Thruflo Geothermal Muffer, ready for acoustical testing. Above it is the straight pipe, against which it will be compared. Steam flowed from left to right.

Below: measuring the sound as the steam passes through the straight pipe (left) and the muffler (right.)

Unfortunately the Thruflo Muffer did not get past the prototype shown above. Some of the mufflers that did make it to The Geysers had a difficult time of it.

TIP # 018 : RAM KEY ADJUSTMENT

After a Hammer has a lot of "mileage" the parts that hold the Piston Rod to the Ram wear a little. This will necessitate some adjustment to insure proper tension of the Ram Keys. If this condition exists in your Hammer and the Ram Keys have a tendenc...

Read More

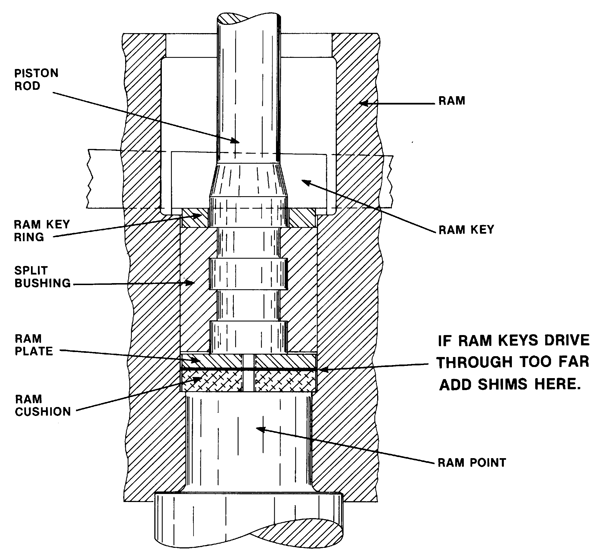

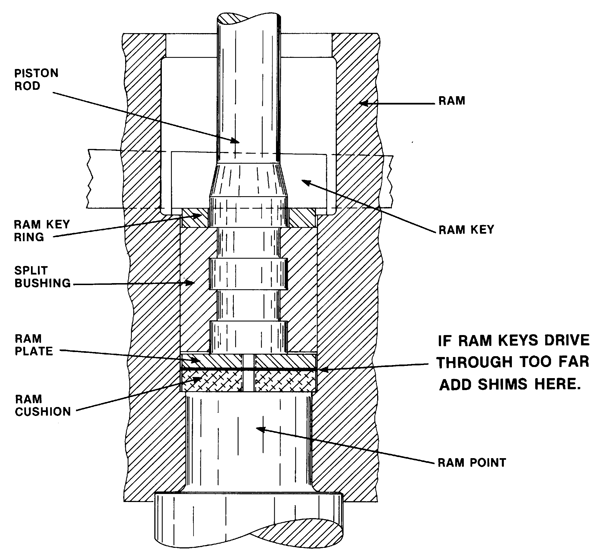

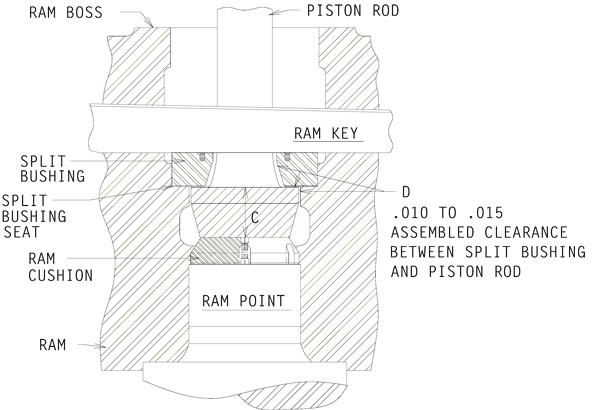

Tip #018: RAM KEY ADJUSTMENT

After a Hammer has a lot of “mileage” the parts that hold the Piston Rod to the Ram wear a little. This will necessitate some adjustment to insure proper tension of the Ram Keys. If this condition exists in your Hammer and the Ram Keys have a tendency to drive through too far, add Shims between the Ram Cushion and the Ram Plate.

After a Hammer has a lot of “mileage” the parts that hold the Piston Rod to the Ram wear a little. This will necessitate some adjustment to insure proper tension of the Ram Keys. If this condition exists in your Hammer and the Ram Keys have a tendency to drive through too far, add Shims between the Ram Cushion and the Ram Plate.

TIP # 019 : VALVE LINER

All Hammers shipped from the factory now are equipped with a Valve Liner. When the Valve Seat area is worn the Valve Liner can easily and quickly be replaced. This eliminates the old time consuming and expensive re-machining of the Valve Seat. The...

Read More

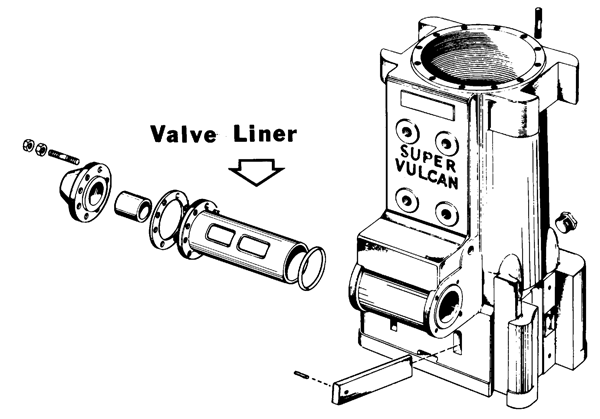

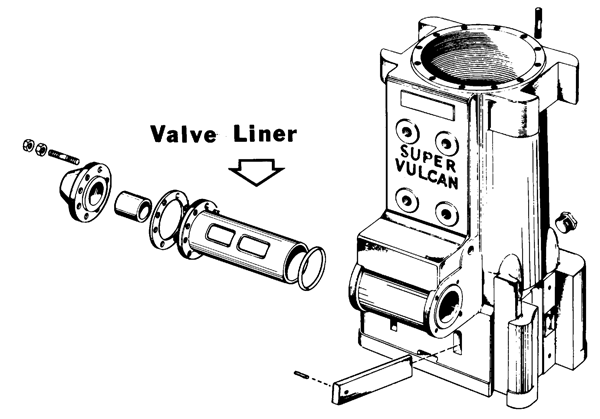

Tip #019: VALVE LINER

All Hammers shipped from the factory now are equipped with a Valve Liner. When the Valve Seat area is worn the Valve Liner can easily and quickly be replaced. This eliminates the old time consuming and expensive re-machining of the Valve Seat. The Liner also allows Valve timing in the field with field tools and less than an hour’s time.

All Hammers shipped from the factory now are equipped with a Valve Liner. When the Valve Seat area is worn the Valve Liner can easily and quickly be replaced. This eliminates the old time consuming and expensive re-machining of the Valve Seat. The Liner also allows Valve timing in the field with field tools and less than an hour’s time.

Old style Vulcan Hammers can be machined to fit the new Liner. Contact the factory for instructions.

TIP # 020 : EXTRACTOR BUMPER CONVERSION

Until recent years Vulcan Pile Extractors utilized a Steel Spring and Spring Guide in the Cylinder head as shown below: To convert older Extractors to the new configuration which replaces the Spring and Spring Guide with a Rubber Bumper the pr...

Read More

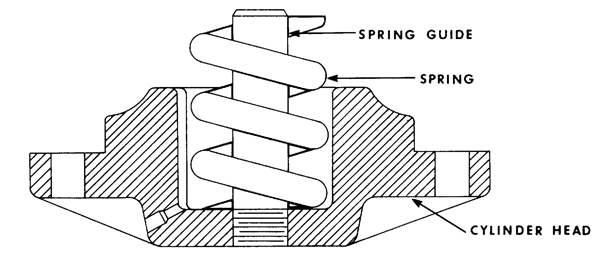

Tip #020: EXTRACTOR BUMPER CONVERSION

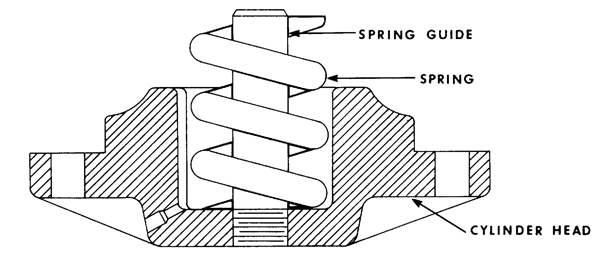

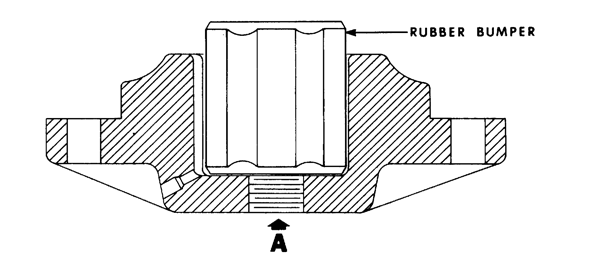

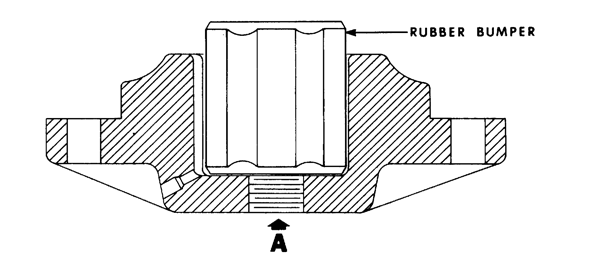

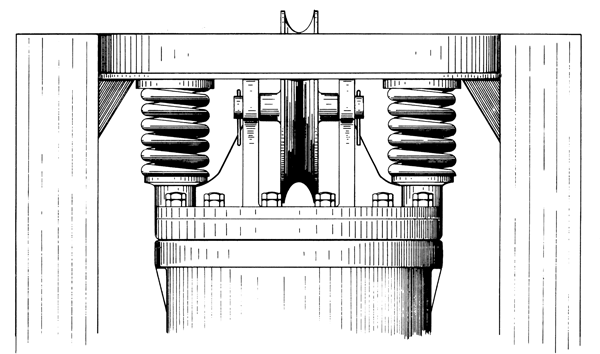

Until recent years Vulcan Pile Extractors utilized a Steel Spring and Spring Guide in the Cylinder head as shown below:

To convert older Extractors to the new configuration which replaces the Spring and Spring Guide with a Rubber Bumper the procedure is as follows:

- Drill through at “A” 1 1/2″ diameter.

- Remove Spring Guide and discard.

- Tap hole for 1 1/4″ NPT.

- Insert countersunk Pipe Plug 1 1/4″ size.

- Install Bumper as shown.

TIP # 021 : SLIDE BAR SHIM

When checking the position of the Slide Bar if you find it below the correct position, add the Shim BELOW THE SLIDE BAR END BLOCK, as shown above. Shims installed under the Slide Bar, for obvious reasons, will create problems...

Read More

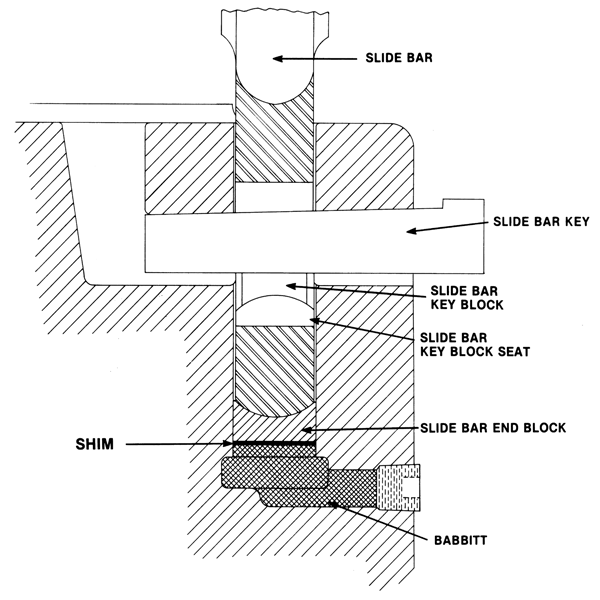

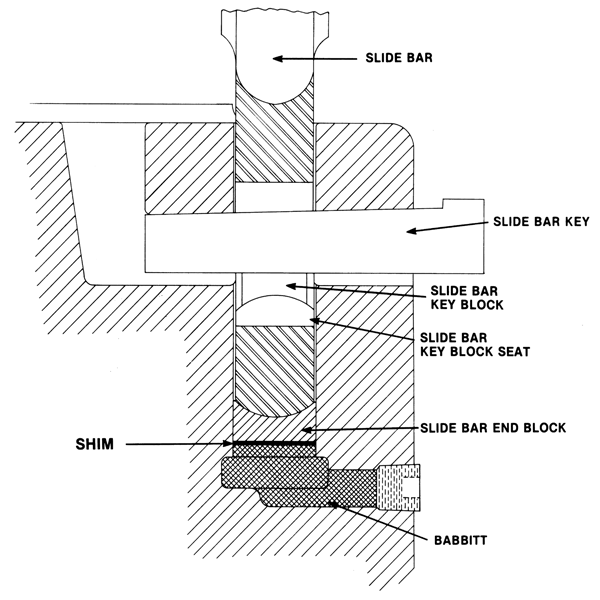

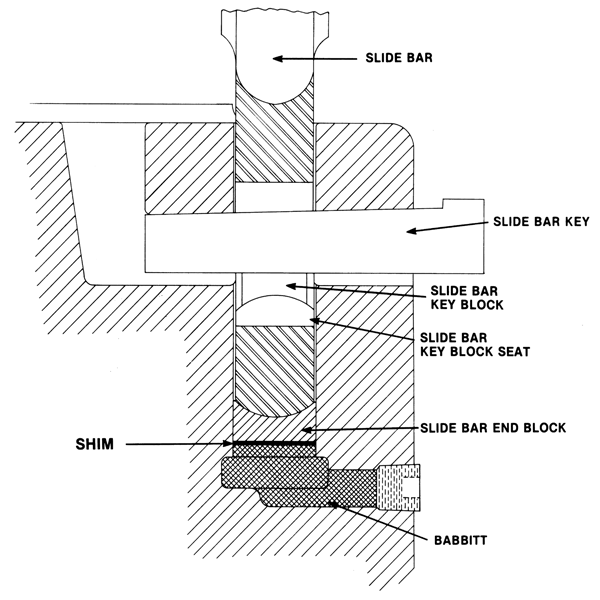

Tip #021: SLIDE BAR SHIM

When checking the position of the Slide Bar if you find it below the correct position, add the Shim BELOW THE SLIDE BAR END BLOCK, as shown above. Shims installed under the Slide Bar, for obvious reasons, will create problems.

When checking the position of the Slide Bar if you find it below the correct position, add the Shim BELOW THE SLIDE BAR END BLOCK, as shown above. Shims installed under the Slide Bar, for obvious reasons, will create problems.

TIP # 022 : REPLACING SLIDE BAR BABBITT

Remove Ram Pipe Plug. Remove old Babbitt by melting with torch. Position Slide Bar "A" and Slide Bar End Block "B" with respect to Ram boss area. Pour molten Babbitt into cavity at "C" until the Babbitt is 3/4" from the outer surface of the...

Read More

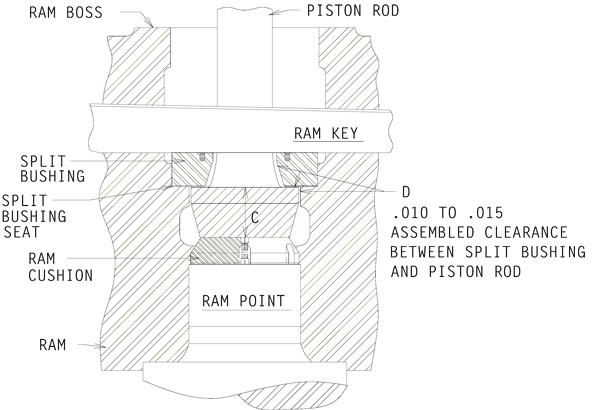

Tip #022: REPLACING SLIDE BAR BABBITT

- Remove Ram Pipe Plug.

- Remove old Babbitt by melting with torch.

- Position Slide Bar “A” and Slide Bar End Block “B” with respect to Ram boss area.

- Pour molten Babbitt into cavity at “C” until the Babbitt is 3/4″ from the outer surface

of the Ram.

- Reinstall Ram Pipe Plug after Babbitt has solidified.

Caution: Use only medium hard Babbitt metal equivalent to Glyco B. DO NOT USE LEAD.

Note: Many compositions of Babbitt contain lead. Be sure to follow all applicable safety and environmental regulations when using babbitt. At one point, Tennessee OSHA required Vulcan to conduct airborne lead tests in the assembly area where babbitt was used. Lead levels detected were below applicable standards. Your results may vary.

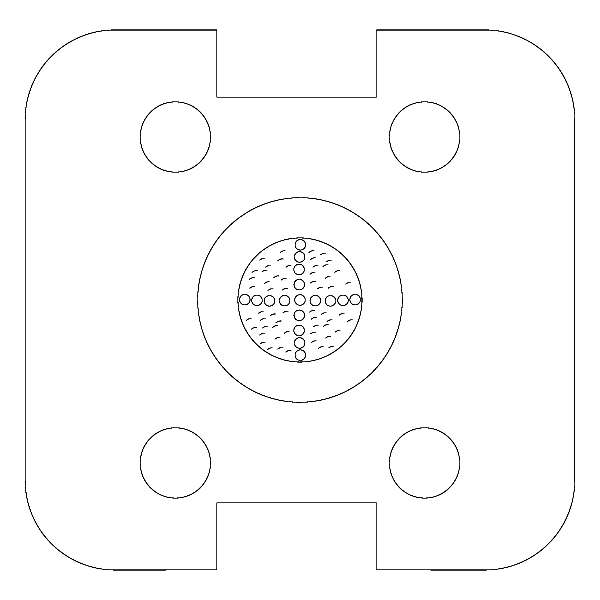

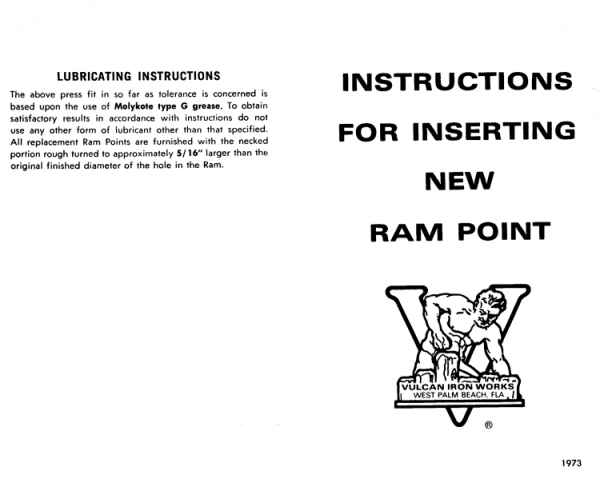

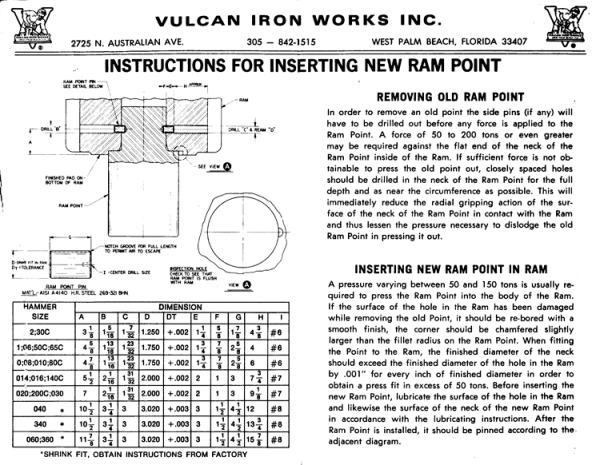

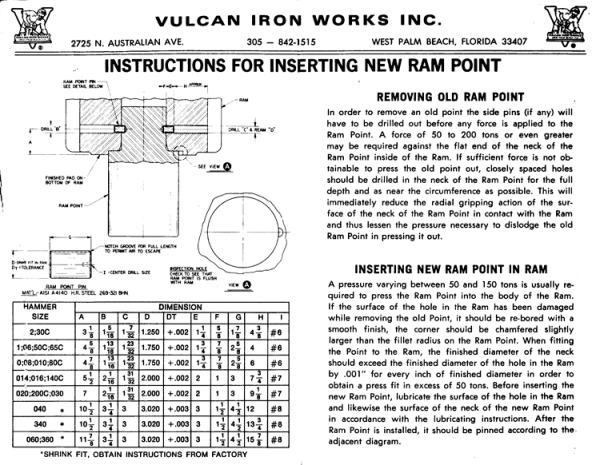

TIP # 023 : INSERTING NEW RAM POINT IN RAM

Vulcan Hammer Guide To Pile Driving Equipment...

Read More

TIP # 024 : REMOVING BROKEN RAM POINT

When Ram Point failures occur. it is generally true that they break through he neck of the point at or near the bottom surface of the Ram. It is most usually almost impossible to press out the broken neck portion of the point from the Ram. The proper...

Read More

Tip #024: REMOVING BROKEN RAM POINT

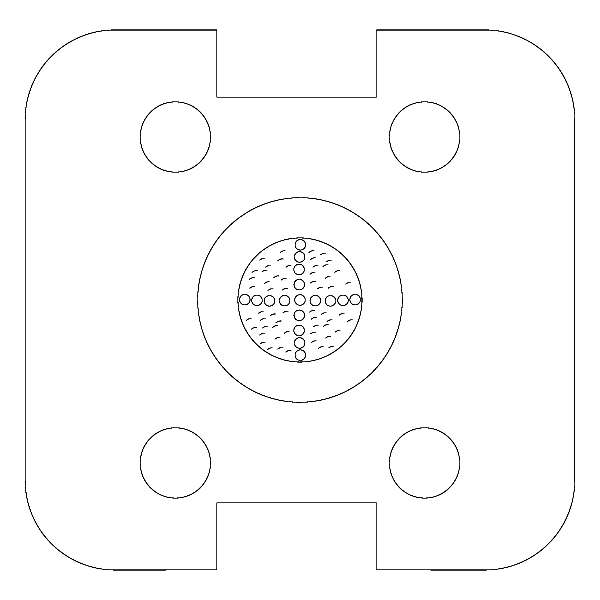

When Ram Point failures occur. it is generally true that they break through he neck of the point at or near the bottom surface of the Ram. It is most usually almost impossible to press out the broken neck portion of the point from the Ram. The proper and easiest method of removal is as follows:

When Ram Point failures occur. it is generally true that they break through he neck of the point at or near the bottom surface of the Ram. It is most usually almost impossible to press out the broken neck portion of the point from the Ram. The proper and easiest method of removal is as follows:

- If the Ram Point is pinned, it is necessary to drill out the Pins prior to proceeding.

- After Pins (if present) are removed, drill a series of holes (see below) in a cross configuration through the Ram Point neck portion. Do not place these holes closer than 1/4″ to the Base into which the Ram Point is fitted. With a torch, burn the metal from between the series of holes drilled. This will relieve the radial pressure on the Ram Point. After this is done, press out the remaining portion of the Ram Point.

Depending on bore condition it may be necessary to hone or re-bore the Ram. This should be done before inserting new Ram Point.

TIP # 025 : SIDE CHANNEL MODIFICATION

Many of our contractor customers have in the past modified the installation of Pile Hammer Side Channels to provide the following: Spring mounting of Channels to prevent attrition during extremely hard driving. Spring mounting of a Hammer Ada...

Read More

Tip #025: SIDE CHANNEL MODIFICATION

Many of our contractor customers have in the past modified the installation of Pile Hammer Side Channels to provide the following:

- Spring mounting of Channels to prevent attrition during extremely hard driving.

- Spring mounting of a Hammer Adapter to adapt one size Hammer to a larger size set of Leaders.

In either case we can provide special Cylinder Head attachments and hardware to implement both alternatives as illustrated below:

Note: What is presented here is a variation of another Raymond innovation: the inboard extension. All Raymond hammers were designed to ride in some kind of extension. The advantage of this is that it makes mating a system of hammers and leaders much simpler if the hammers can be run in more than one set of jaws, and an extension system is the easiest way to accomplish this.

One innovation that Raymond eventually went to was the use of rubber springs in place of the coil ones. In addition to lesser expense, when properly selected the rubber springs do a better job of dampening the hammer vibrations than the steel coil ones. It’s important that the structural integrity of the extension is sufficient to withstand both vibration and handing stresses.

Below: Vulcan 06 hammer riding in an extension.

TIP # 026 : COLUMN REMOVAL

It is frequently encountered when overhauling Pile Hammers that Columns will be stuck in the Cylinder and occasionally in the Base of the Hammer. This occurs for many reasons ranging from excessive corrosion or badly burred parts. The easiest way to...

Read More

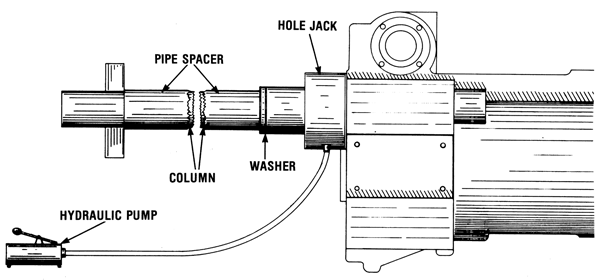

Tip #026: COLUMN REMOVAL

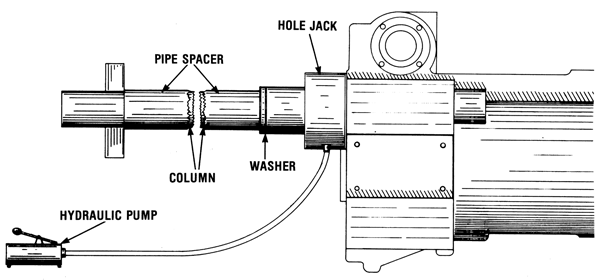

It is frequently encountered when overhauling Pile Hammers that Columns will be stuck in the Cylinder and occasionally in the Base of the Hammer. This occurs for many reasons ranging from excessive corrosion or badly burred parts. The easiest way to remove such Columns is shown below.

- Use a center hole jack (100 ton capacity) with sufficient hole diameter to slide over the Column. This should be so positioned so that the ram of the jack is away from the Cylinder, (i.e.) thrust in direction of arrow.

- Use a 3/4″ thick washer of suitable inside diameter.

- For the length of the Column from the jack to the keyway insert a pipe spacer.

- Insert in the keyway of the Column a Column Key or steel bar to provide backup for jacking.*

- After this assembly is complete, commence jacking.

*If the lower end of the Column is broken off and no full keyway is available lugs may be welded to the Column to provide jacking back-up.

Note: The tip is not clear on this, but the procedure described above probably only applies to smaller Vulcan hammers.

Jacking columns and other parts out of rusted or well used hammers is a procedure that occurs regularly in the overhaul of Vulcan hammers. It is one, however, that requires special attention to safety. The parts used must be thick enough to withstand the loads, and personnel must stand clear during the operation in case a part gives way and results in a “missile reaction.”

TIP # 027 : BUSHING REPLACEMENT

The use of bronze bushings in Vulcan products is limited to head sheaves and steam chest heads. From time to time it is necessary to replace these bushing. All of these bushings are press fitted. Sometimes the parts into which these bushings are pres...

Read More

Tip #027: BUSHING REPLACEMENT

The use of bronze bushings in Vulcan products is limited to head sheaves and steam chest heads. From time to time it is necessary to replace these bushing. All of these bushings are press fitted. Sometimes the parts into which these bushings are pressed are oversize in bore for a variety of reasons. When this occurs. the factory supplied bushing will not fit tightly. Rather than make a special bushing, there is a simple method of adjusting the fit of the bushings for press fitting.

| Step I — Place bushing on an arbor and put in engine lathe. Using fine diamond-point knurling rolls, double knurl the outer surface of the bushing. Be sure to use a good quality cutting oil during the knurling operation. After knurling, degrease the bushing prior to proceeding with the next step. |

|

| Step 2 — Make sure that the hole into which the bushing is to be inserted is clean, dry and free of burrs. The outside of the bushing should look like the illustration. Using no lubricant press the bushing into the piecepart. |

|

TIP # 028 : INSTALLATION OF BLIND PISTON RINGS

Lower piston rings in the case of the Super Vulcan and the DGH series hammers, and upper piston rings in the case of Vulcan Pile Extractors, require a special installation technique. This special technique is necessitated by the fact that in these th...

Read More

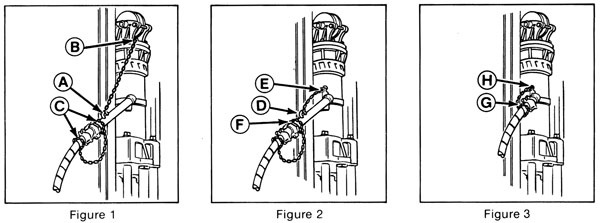

Tip #028: INSTALLATION OF BLIND PISTON RINGS

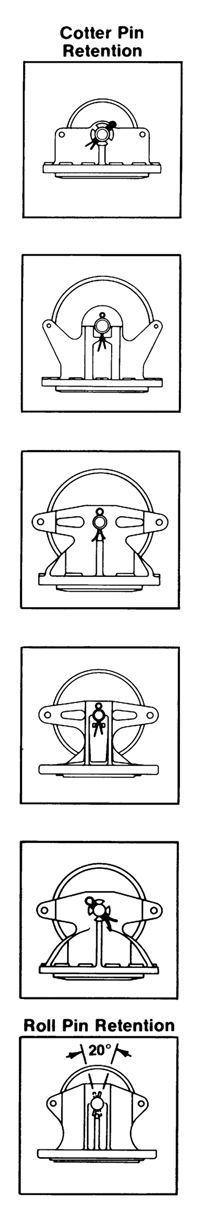

Lower piston rings in the case of the Super Vulcan and the DGH series hammers, and upper piston rings in the case of Vulcan Pile Extractors, require a special installation technique. This special technique is necessitated by the fact that in these three product lines, the piston and the piston rings affixed thereto must enter the cylinder in which they function unaided by such devices as piston ring compressors or installers. Additionally it is impossible to visually check the piston ring as it enters its cylinder. The procedure is not unduly complicated if the following steps are carefully executed. The three illustrations below show the general method to be described in steps.

- Examine carefully the piston ring grooves for any burrs or dirt. Deburr if necessary and make sure the grooves are clean.

- Expand the piston rings and snap them into their respective grooves making sure that they rotate freely.

- Raise the end of the piston ring at the gap with a fine point screwdriver or other sharp instrument and place behind the ring a piece of water soluble paper (cigarette paper or toilet tissue is suitable for this purpose).

- Using a lead or bronze hammer, carefully tap the piston ring at the point of insertion of the paper into the groove where it will be wedged in place by the paper.

- Repeat this procedure with the other end of the piston ring and in the process or tapping the ring into the groove, be sure that the gap in thepiston ring is as nearly closed as possible.

- After the rings are so wedged into the grooves, the piston is now ready for installation in the unit.

Moisture in the steam or compressed air will soften the paper used to wedge the rings and they will expand to their normal operating position in a short period of time after the unit is laced in operation.

TIP # 029 : EQUIPMENT HANDLING

While Pile Hammers are not unduly difficult to handle there are some basic precautions to be observed as well as some basic Do's and Don'ts. Note: Hammer handing as "not unduly difficult" only applies to specialists in material handing...

Read More

Tip #029: EQUIPMENT HANDLING

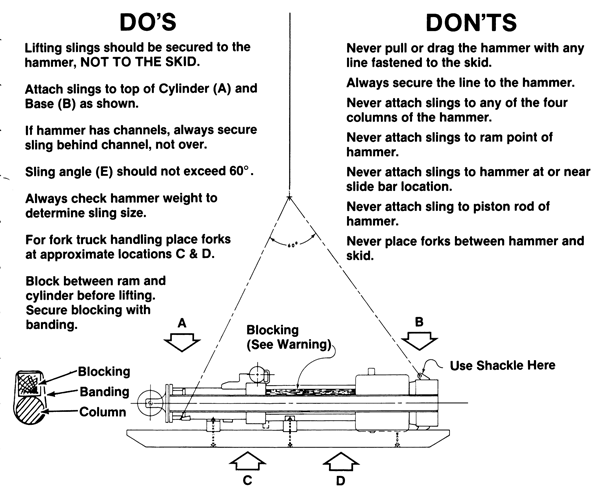

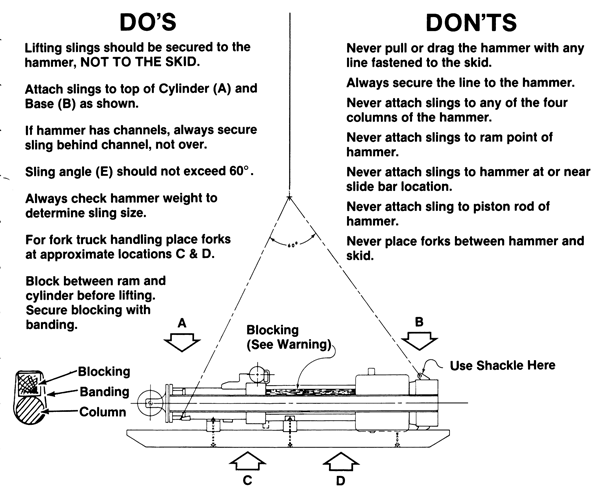

While Pile Hammers are not unduly difficult to handle there are some basic precautions to be observed as well as some basic Do’s and Don’ts.

Note: Hammer handing as “not unduly difficult” only applies to specialists in material handing.

TIP # 030 : STRIPPED THREAD REPAIRS

It is frequently found in older hammers that stud hole threads will sometimes become stripped of sufficient holding thread as to necessitate some form of repair. Generally speaking there am two alternate methods of effecting this repair the first is...

Read More

Tip #030: STRIPPED THREAD REPAIRS

It is frequently found in older hammers that stud hole threads will sometimes become stripped of sufficient holding thread as to necessitate some form of repair. Generally speaking there am two alternate methods of effecting this repair the first is to drill out oversize the stripped hole, insert a plug and redrill and retap to original size. The second alternate is to drill out the stripped hole oversize and install oversize studs or screws as the case may be. The disadvantage to this is it is then necessary to resize the holes in the mating parts.

The recommended procedure is the use of Heli-Coil®. Heli-Coil inserts are thread bushings coiled from formed diamond shaped wire. They are wound into tapped holes to form Standard size internal threads. The procedure is simple.

Step I – Drill out the stripped hole with the specified drill size to the appropriate Heli-Coil insert.

Step 2 – Tap the new hole with special Heli-Coil tap.

Step 3 – Install thread sleeve with Heli-Coil inserter and your tapped hole is back to standard.

The Heli-Coil salvage procedure is acceptable to military and industrial standards and affords easy repair to your hammers and extractors. Heli-Coil products while not sold by Vulcan Iron Works Inc- are available from Heli-Coil Products, Division of Mite Corporation, Danbury, Connecticut 06810, or their distributors. This type of product is normally marketed through industrial mill supply houses.

Heli-Coil® is the registered trade mark of the Mite Corporation.

TIP # 031 : BROKEN STUD REMOVAL

Probably one of the most annoying problems in hammer repair is the removal of broken studs or screws. Shown below is an easy and proven method of removing the broken portion of the stud or screw without damage to the tapped hole. Apply generous...

Read More

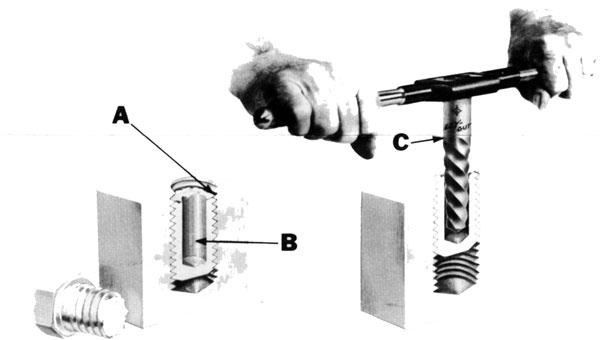

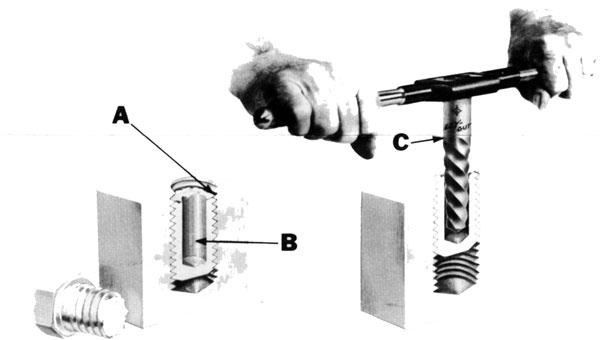

Tip #031: BROKEN STUD REMOVAL

Probably one of the most annoying problems in hammer repair is the removal of broken studs or screws. Shown below is an easy and proven method of removing the broken portion of the stud or screw without damage to the tapped hole.

Probably one of the most annoying problems in hammer repair is the removal of broken studs or screws. Shown below is an easy and proven method of removing the broken portion of the stud or screw without damage to the tapped hole.

- Apply generous quantity of penetrating oil to stub of stud and let stand overnight if possible (Letter A).

- Drill hole in broken stud as shown (Letter B). See table below for size of drill.

- Using Ezy-Out® as shown (Letter C) back out broken portion of stud. See table below for size of Ezy-Out®.

|

EZY-OUT® NO.

|

DRILL SIZE

|

STUD/SCREW SIZE

|

|

5

|

17/64″

|

9/16″-3/4″

|

|

6

|

13/32″

|

3/4″-1″

|

|

7

|

17/32″

|

1″-1 3/8″

|

|

8

|

13/16″

|

1 3/8″-1 3/4″

|

|

9

|

1 1/16″

|

1 1/34″-2 1/8″

|

|

10

|

1 5/16″

|

2 1/8″-2 1/2″

|

|

11

|

1 9/16″

|

2 1/2″-3″

|

|

12

|

1 15/16″

|

3″-3 1/2″

|

|

EZY-OUT® IS THE REGISTERED TRADEMARK OF THE CLEVELAND TWIST DRILL CO.

|

TIP # 032 : COLUMN SALVAGE

Vulcan Hammer Guide To Pile Driving Equipment...

Read More

TIP # 033 : BASE/CYLINDER COLUMN HOLE REPAIR

Tip no longer available, due to involved nature of repair...

Read More

Tip #033: BASE/CYLINDER COLUMN HOLE REPAIR

Tip no longer available, due to involved nature of repair.

TIP # 034 : STEAM CHEST VALVE LINERS

Replaceable Steam Chest Valve Liners are standard equipment in all Vulcan Single and Differential Acting Pile Hammers These Valve Liners were adopted to provide easy means of replacing worn surfaces in the Steam Chest in lieu of reboring. Given belo...

Read More

Tip #034: STEAM CHEST VALVE LINERS

Replaceable Steam Chest Valve Liners are standard equipment in all Vulcan Single and Differential Acting Pile Hammers These Valve Liners were adopted to provide easy means of replacing worn surfaces in the Steam Chest in lieu of reboring.

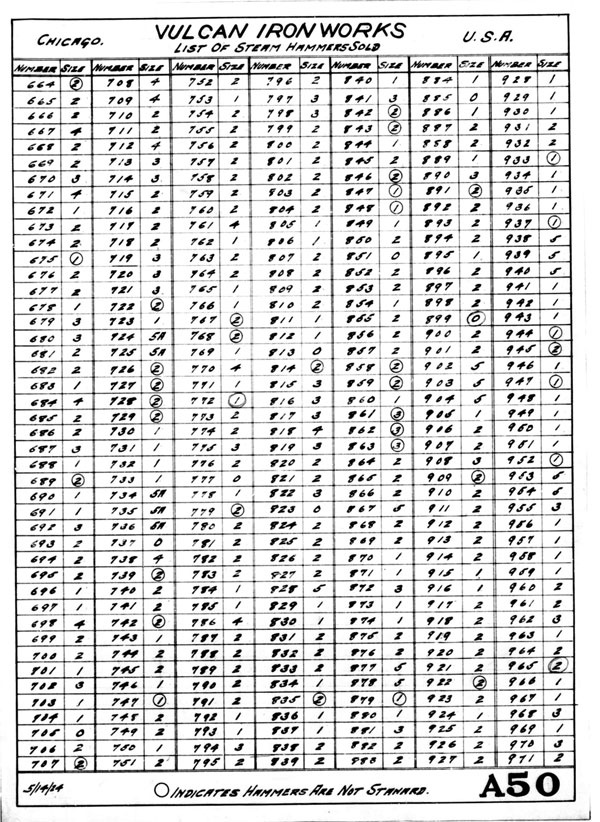

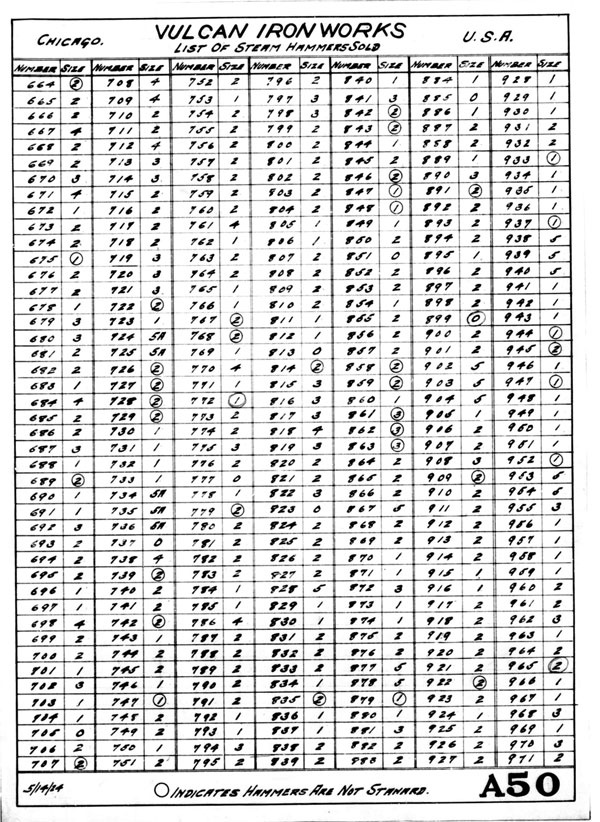

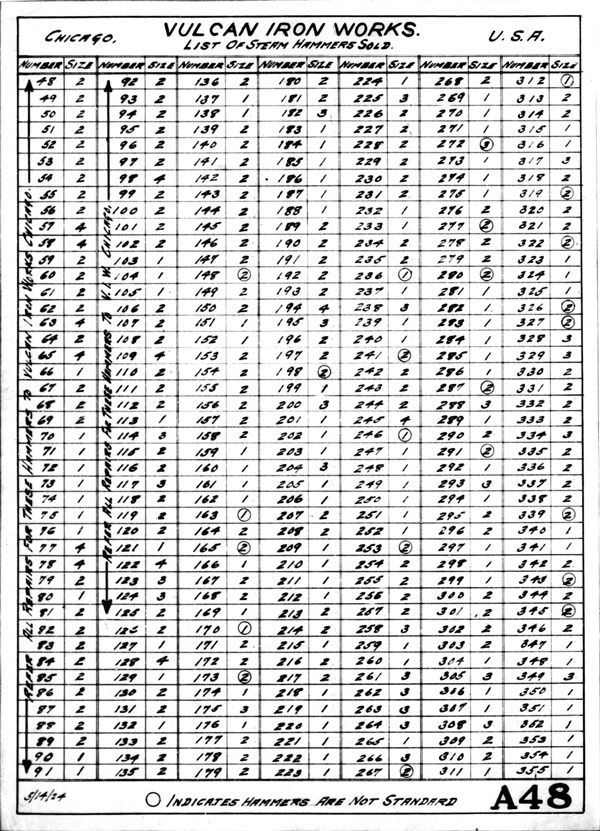

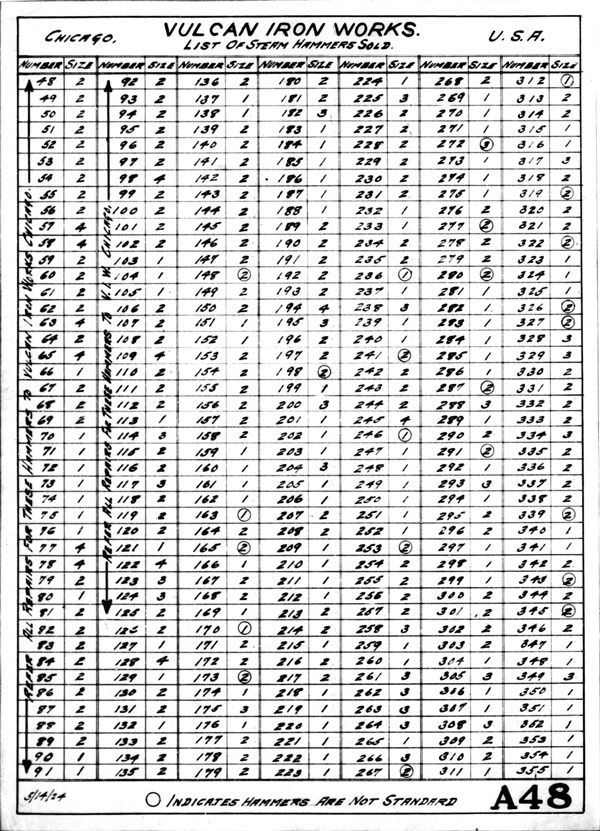

Given below in the table are the Serial Numbers and dates of the first hammer in each size to be equipped with Valve Liners. All hammers with Serial Numbers subsequent to those given for each size of Hammer are equipped with Valve Liners.

As changes take place. additional data will be provided.

| Hammer Size |

Serial Number & Date

|

| Onshore Std. |

Onshore Cable |

Offshore (Raised Steam Chest) |

Offshore (Lowered Steam Chest) |

| #2 |

FG-5335/11-29-67 |

|

|

|

| #1 |

FG-5280/10-23-67 |

|

|

|

| 06 |

FG-5465/12-21-67 |

|

|

|

| 106 |

FI-6180/4-21-69 |

|

|

|

| 08 |

FG-5205/9-11-67 |

GD-9200/12-4-74 |

|

|

| 010 |

FG-5240/9-27-67 |

GD9035/8-8-74 |

|

FJ-6700/6-26-70 |

| 014 |

FG-5345/12-16-67 |

|

|

|

| 016 |

FI-6335/7-15-69 |

|

|

FG-4075/4-4-67 |

| 020 |

FG-5190/8-19-67 |

|

|

FH-5530/2-24-68 |

| 030 |

|

|

|

FH-5645/4-19-68 |

| 040 |

|

FI-6240/5-8-69 |

|

FG-5330/12-8-67 |

| 340 |

|

|

|

GC-8245/2-12-73 |

| 540 |

|

|

|

GD-8800/5-22-74 |

| 060 |

|

|

|

FH-5555/6-15-68 |

| 360 |

|

|

|

GD-9025/7-19-74 |

| 560 |

|

|

|

GC-8445/7-18-73 |

| 3100 |

|

|

|

GE-9450/6-11-75 |

| 30C |

FH-5520/2-12-68 |

|

|

|

| 50C |

FG-5150/9-22-67 |

FH-5805/8-15-68 |

|

|

| 65C |

FG-5300/11-2-67 |

|

|

|

| 80C |

FG-4040/2-17-67 |

|

|

|

| 85C |

FI-6100/1-7-69 |

|

|

|

| 100C |

GA-7590/11-12-71 |

|

|

|

| 140C |

FF-3005/1-20-67 |

|

|

|

| 200C |

FH-5570/3-8-68 |

|

GA-7595/11-11-71 |

|

Note: This was never followed up on. But in reality there was no need to, as virtually any Vulcan hammer made after 1970 (those with a serial number starting with a “G”, “H” or “I”) had a valve liner. In addition to providing a replaceable wear surface, the valve liner eliminated the need to cut the valve stems custom for each hammer by providing a consistent location for the ports.

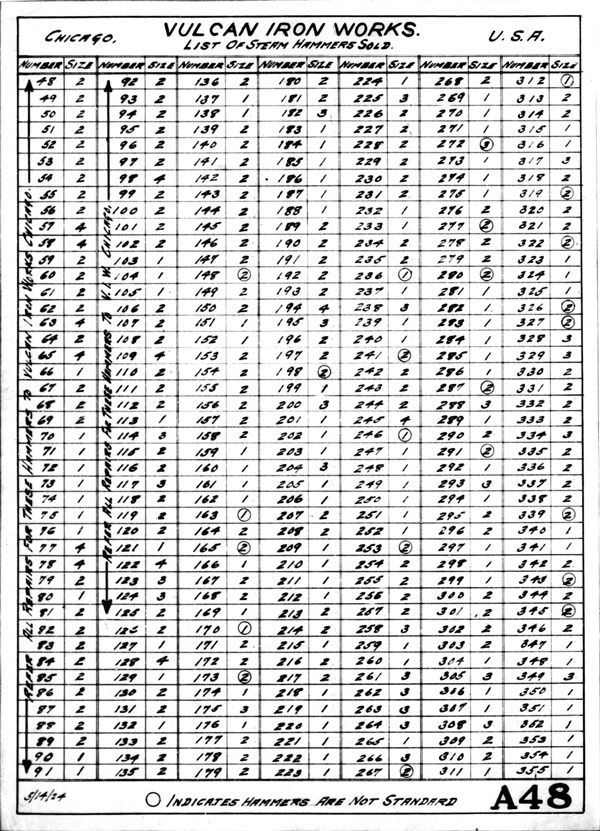

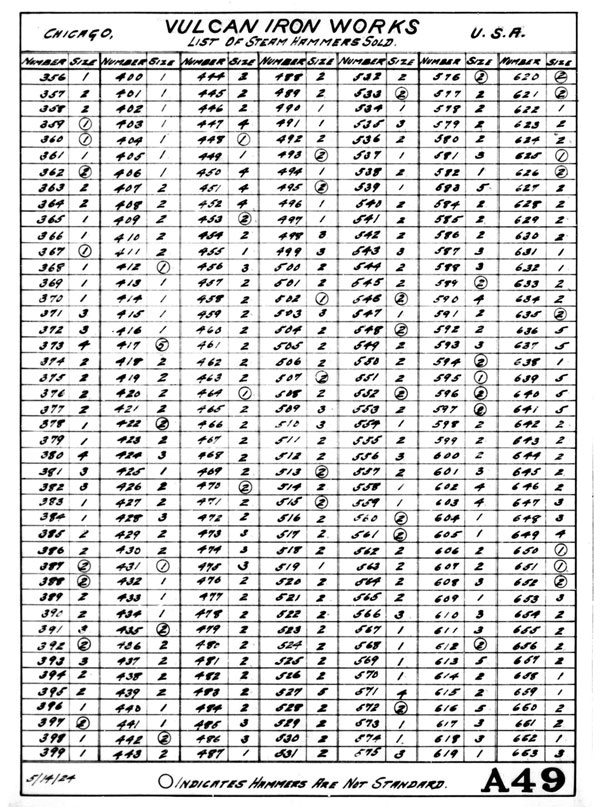

TIP # 035 : SERIAL NUMBERS

It is frequently desirable to ascertain the age of equipment for appraisal, evaluation and a variety of other reasons. As is customary in most construction equipment, we show below the year of manufacture and the serial number range for that particul...

Read More

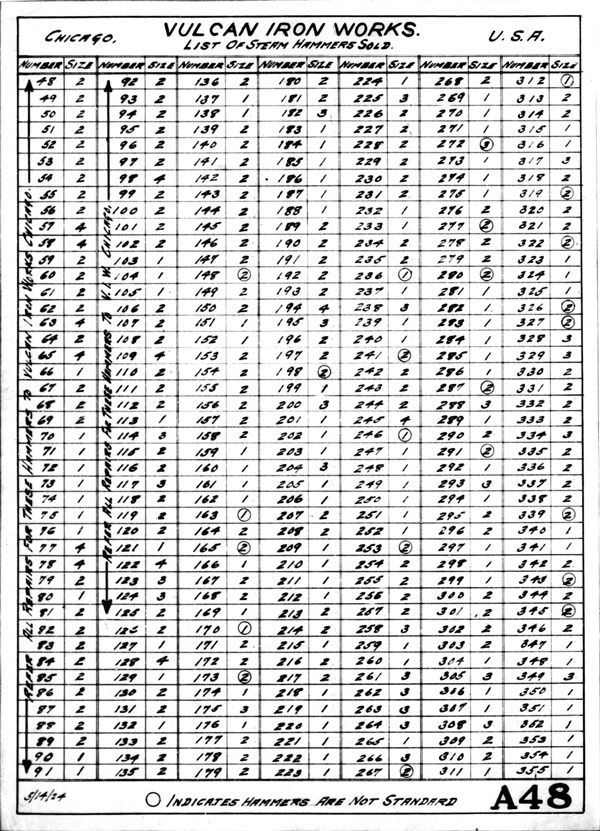

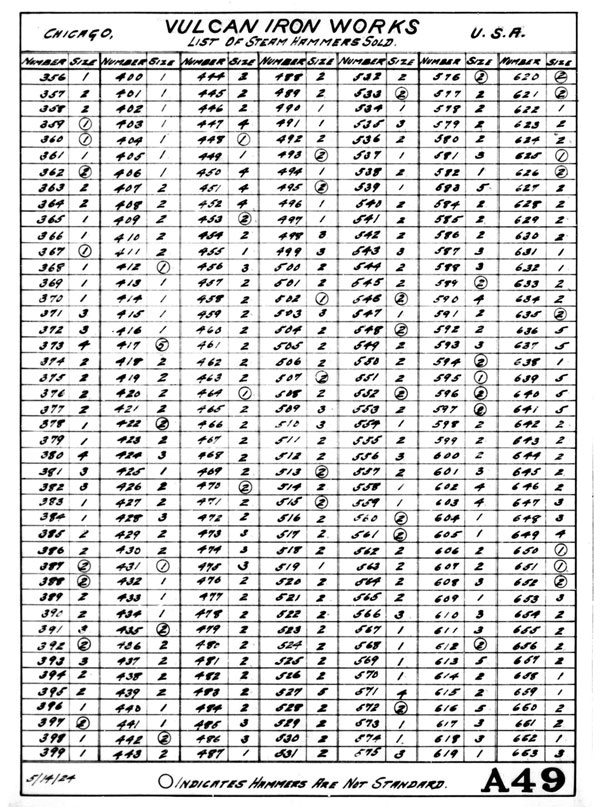

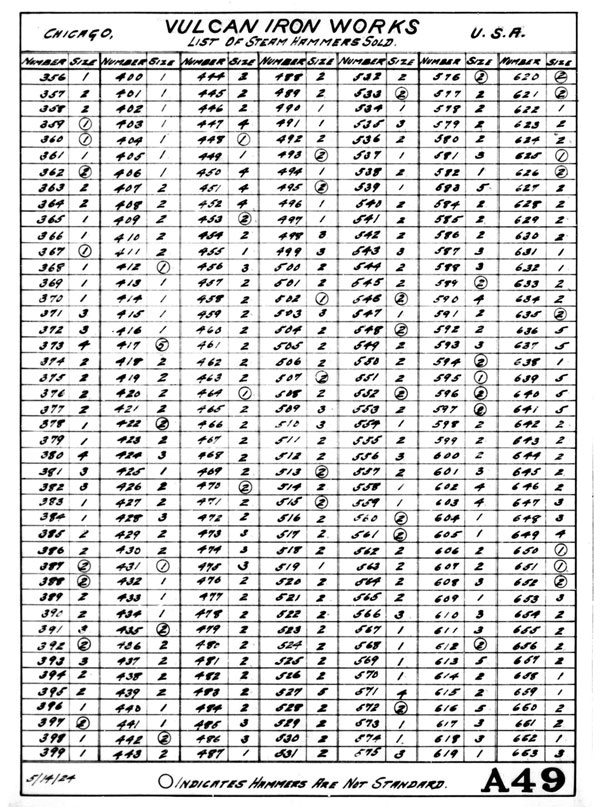

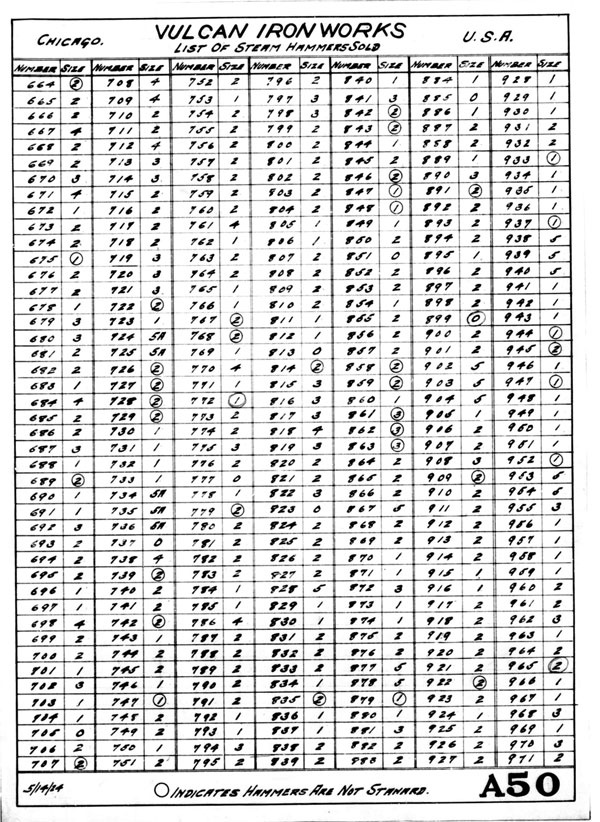

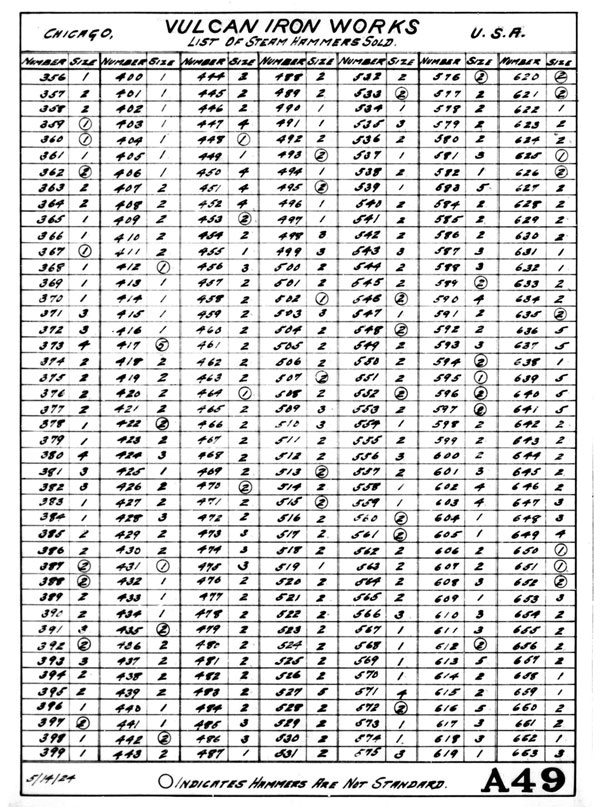

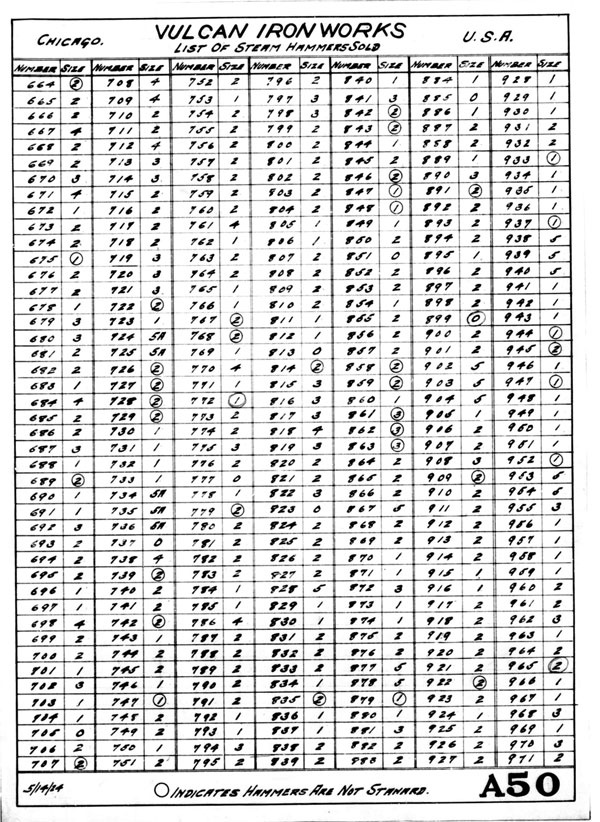

Tip #035: SERIAL NUMBERS

It is frequently desirable to ascertain the age of equipment for appraisal, evaluation and a variety of other reasons. As is customary in most construction equipment, we show below the year of manufacture and the serial number range for that particular year. As we approach one hundred years of serial numbers, we will on a yearly basis update this information.

| YEAR |

S/N RANGE |

YEAR |

S/N RANGE |

YEAR |

S/N RANGE |

YEAR |

S/N RANGE |

| 1888 |

1/7 |

1913 |

771/832 |

1938 |

2504/2546 |

1963 |

48569/48667 |

| 1889 |

8/13 |

1914 |

833/912 |

1939 |

2547/2586 |

1964 |

48668/48777 |

| 1890 |

14/36 |

1915 |

913/994 |

1940 |

2587/2671 |

1965 |

48778/48855

FE665/FE1290 |

| 1891 |

37/45 |

1916 |

995/1041 |

1941 |

2672/2806 |

1966 |

FF1295/FF3050 |

| 1892 |

46/60 |

1917 |

1042/1115 |

1942 |

2807/2902 |

1967 |

FG3055/FG5475 |

| 1893 |

61/73 |

1918 |

1116/1197 |

1943 |

2903/2970 |

1968 |

FH5480/FH6000 |

| 1894 |

74/86 |

1919 |

1198/1231 |

1944 |

2971/3157 |

1969 |

FI6005/FI6555 |

| 1895 |

87/98 |

1920 |

1232/1259 |

1945 |

3158/3199 |

1970 |

FJ6700/FJ6755

GJ6760/GJ7175 |

| 1896 |

99/110 |

1921 |

1260/1321 |

1946 |

3200/3259 |

1971 |

GA7185/GA7670 |

| 1897 |

111/124 |

1922 |

1322/1374 |

1947 |

3260/3328 |

1972 |

GB7675/GB8200 |

| 1898 |

125 |

1923 |

1375/1431 |

1948 |

3329/3404 |

1973 |

GC8205/GC8690 |

| 1899 |

126/148 |

1924 |

1432/1517 |

1949 |

3405/3464 |

1974 |

GD8695/GD9270 |

| 1900 |

149/157 |

1925 |

1518/1591 |

1950 |

3465/3571 |

1975 |

GE9275/GE9720 |

| 1901 |

158/194 |

1926 |

1592/1665 |

1951 |

3572/3663 |

1976 |

GF100/GF470 |

| 1902 |

195/231 |

1927 |

1666/1777 |

1952 |

3664/3747 |

1977 |

See Note Below |

| 1903 |

232/241 |

1928 |

1778/1906 |

1953 |

3748/3826 |

1978 |

| 1904 |

242/287 |

1929 |

1907/2039 |

1954 |

3827/3898 |

1979 |

| 1905 |

288/352 |

1930 |

2040/2164 |

1955 |

3899/4012 |

1980 |

| 1906 |

353/411 |

1931 |

2165/2258 |

1956 |

4013/4214 |

1981 |

| 1907 |

412/461 |

1932 |

2259/2300 |

1957 |

4215/4363 |

1982 |

| 1908 |

462/507 |

1933 |

2301/2324 |

1958 |

4364/4488 |

1983 |

| 1909 |

508/548 |

1934 |

2325/2364 |

1959 |

4489/4623 |

1984 |

| 1910 |

549/604 |

1935 |

2365/2379 |

1960 |

4624/4747 |

1985 |

| 1911 |

605/690 |

1936 |

2380/2450 |

1961 |

4748/48335 |

1986 |

| 1912 |

691/770 |

1937 |

2451/2503 |

1962 |

48336/48568 |

1987 |

Note: This tip, issued in 1976, was never followed up on; there were never any updates for the offshore tips (there was one in 1977 for the onshore ones; the information from that one is included above.) In fact, by the 1980’s Vulcan took this tip out of its distribution list in fear of people knowing the number of Vulcan hammers outstanding.

However, such updates were, in reality, unnecessary, because in 1965 Vulcan adopted its present system of serial numbers for hammers. This system gave the year of the hammer’s manufacture without having to consult the factory. All of this type of serial number is in the format of

XX-YYYY

where “XX” represents the year code in two letters; they translate into the last two digits of the year as shown in the table on the left. Thus, for a hammer with the serial number prefix “GF” this translates into “76”, thus the hammer was made in 1976. The implementation of these numbers can be seen above.

If you would like more information on this subject, or on a specific hammer serial number, you can fill out the form below and submit it.

TIP # 036 : DOVETAIL REPAIR

As your Vulcan Offshore Hammers grow older, it is unavoidable that wear occurs in the Dovetail Guide in the Cylinder that guides and retains the slide bar. Excessive wear in this Dovetail Guide can cause damage to not only the Slide Bar but the Trip...

Read More

Tip #036: Dovetail Repair

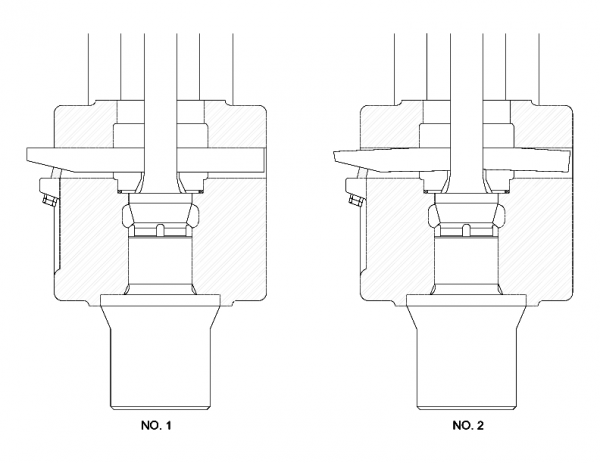

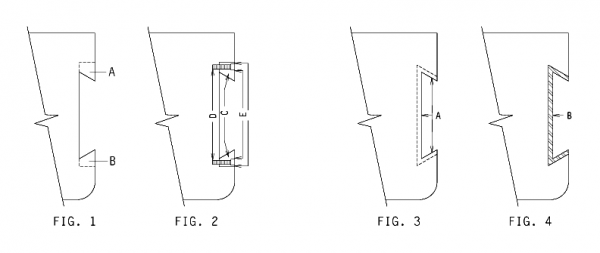

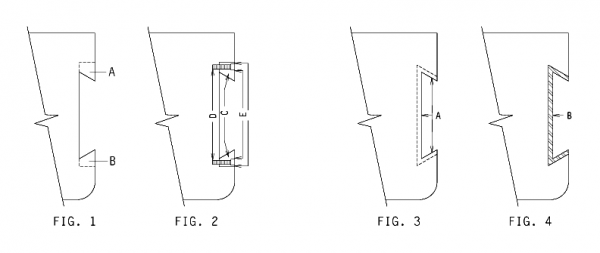

As your Vulcan Offshore Hammers grow older, it is unavoidable that wear occurs in the Dovetail Guide in the Cylinder that guides and retains the slide bar. Excessive wear in this Dovetail Guide can cause damage to not only the Slide Bar but the Trip and the Valve Stem. Where replaceable dovetail inserts are not standard equipment, the following methods of dovetail repair are recommended- Two repair methods are shown below in 1 & 2 depending on wear conditions in the Dovetail.

As your Vulcan Offshore Hammers grow older, it is unavoidable that wear occurs in the Dovetail Guide in the Cylinder that guides and retains the slide bar. Excessive wear in this Dovetail Guide can cause damage to not only the Slide Bar but the Trip and the Valve Stem. Where replaceable dovetail inserts are not standard equipment, the following methods of dovetail repair are recommended- Two repair methods are shown below in 1 & 2 depending on wear conditions in the Dovetail.

Repair method I is recommended when the majority of the wear has taken place on the angular surface of the Dovetail and the bottom flat surface does not require repair. The steps to follow for repair are as follows:

- Remove by machining worn dovetail surfaces as shown at A & B, Illustration #1.

- Manufacture BRONZE replacement gibs of appropriate size. as shown at C, Illustration #2. SAE 660 Bronze is recommended.

- Drill and tap Cylinder for cap screws as shown at D, Illustration #2.

- After installation of gibs, it is necessary to centerpunch each cap screw in at least three locations on its periphery to prevent backout as shown at E, Illustration #2.

Repair method 2 is recommended when wear has taken place on all three Dovetail surfaces (bottom and two angular sides). The steps to follow for repair are as follows:

- Remove by machining 1/16″ of surface metal on all three surfaces as shown at A, Illustration #3. This is to remove work hardened surfaces from worn areas.

- Build up all three surfaces with sufficient material to allow for remachining by either of the following methods:

- Arc brazing with Bronze rod.

- Arc welding with 100% Nickel rod.

- Gas brazing and gas welding are not recommended for cast iron material in this area of the cylinder.

- Remachine built up Dovetail area back to original factory dimensions as at B, Illustration #4.

IMPORTANT

When restoring Slide Bar Dovetails, it is absolutely essential that restored surfaces conform to original dimensional relationships with the center lines of the cylinder and Valve Chest. Contact factory for specific dimensions before proceeding.

Note: Method #1 seldom addresses real dovetail repair problems because the dovetail seldom wears only on the angled surfaces, but on the back as well. A more satisfactory solution to this problem would be to use the removable and replaceable Slide Bar Guide Block as Raymond used, but Vulcan never adopted this solution on its hammers.

TIP # 037 : VARI-CYCLE HAMMERS

Vulcan Vari-Cycle (Stroke Control) is available for all Vulcan Single Acting Hammers having a cylinder which has as an integrally cast pad part thereof the necessary mounting pads for installation of the Vari-Cycle equipment. Shown in the table below...

Read More

Tip #037: VARI-CYCLE HAMMERS

Vulcan Vari-Cycle (Stroke Control) is available for all Vulcan Single Acting Hammers having a cylinder which has as an integrally cast pad part thereof the necessary mounting pads for installation of the Vari-Cycle equipment. Shown in the table below are the first Serial Number and date of those hammers (by size) having Vari-Cycle factory installed or mounting pads for field retrofit.

| Hammer Size |

Serial Numbers and Date |

| Onshore Hammers |

Offshore Hammers |

| #1 |

See Note 1 |

– |

| 06 |

See Note 2 |

– |

| 08 |

GB-8095/10-27-72 |

– |

| 010 |

GB-8100/11-2-72 |

– |

| 014 |

FI-6250/5-13-69 |

– |

| 016 |

FI-6515/12-19-69 |

FH-5500/2-1-68 |

| 020 |

FG-5190/12-19-69 |

FH-5530/2-15-68 |

| 030 |

– |

FH-5645/4-19-68 |

| 040 |

– |

FG-5330/12-8-67 |

| 340 |

– |

GC-8245/2-12-73 |

| 540 |

– |

GD-8800/5-22-74 |

| 060 |

– |

FH-5555/6-15-68 |

| 360 |

– |

GD-9025/7-19-74 |

| 560 |

– |

GC-8445/7-18-73 |

| 3100 |

– |

GE-9450/6-11-75 |

All Hammers having Serial Numbers subsequent to those above are configured as to accommodate Vari-Cycle.

Note 1 — The following Size #1 Hammers are equipped with mounting pads for Vari-Cycle:

GC-8455/GC-8555/GC-8595/GC-8715/GC-8765

Vari-Cycle mounting pads on this size Hammer were discontinued 8-23-74.

Note 2 — The following Size 06 Hammers are equipped with mounting pads for Vari-Cycle:

GD-8750/GD-8740/GD-8825/GD-8605/GC-8605/GC-8685

Van-Cycle mounting pads on this size Hammer were discontinued 7-24-74

Note: This tip obviously does not cover the hammers later than the mid-1970’s, especially the onshore 5′ stroke hammers. Their situation is complicated; you can contact us to ask questions about this. All of the Vulcan 5100, 5110, 5150 and 6300 hammers can accommodate Vari-Cycle and indeed virtually all offshore hammers from the 1970’s onward were either equipped with Vari-Cycle or Traverse Trip.

TIP # 038 : COMPRESSED AIR VELOCITY FUSE

In the new Department of Labor hammer-tips Regulations for Construction, it states in the Federal Register, Volume 36, Number 75, that "all hoses exceeding 1/2 inch inside diameter shall have a hammer-tips device at the source of supply or branch line to reduc...

Read More

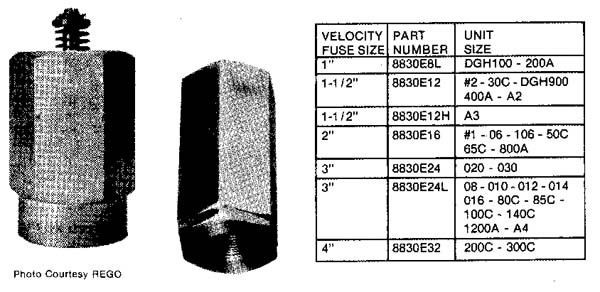

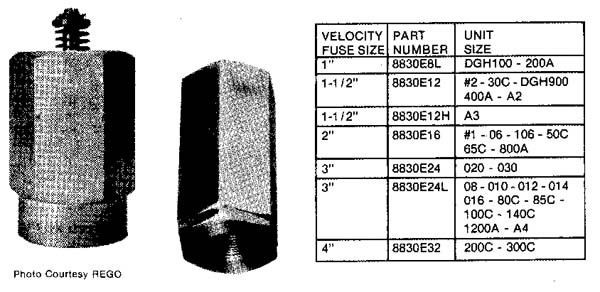

Tip #038: COMPRESSED AIR VELOCITY FUSE

In the new Department of Labor Safety Regulations for Construction, it states in the Federal Register, Volume 36, Number 75, that “all hoses exceeding 1/2 inch inside diameter shall have a safety device at the source of supply or branch line to reduce pressure in case of hose failure.”

In the new Department of Labor Safety Regulations for Construction, it states in the Federal Register, Volume 36, Number 75, that “all hoses exceeding 1/2 inch inside diameter shall have a safety device at the source of supply or branch line to reduce pressure in case of hose failure.”

The “Velocity Fuses” shown below left now enable you to meet these requirements. They are specifically designed for use on compressed air lines loading to pneumatic tools These valves protect personnel from dangerous whipping air hoses caused by a suddenly disconnected coupling or severed air hose while the line is under pressure.

OPERATION

The valve automatically slams shut when the flow of air exceeds the setting of the valve. A tiny orifice or “bleed hole” allows enough air through the valve to equalize pressure. After repairs are made and air pressure is back to normal flow, the valve automatically re-opens to allow full flow and afford the same protection again The velocity fuses referred to above in sizes 1″ and larger are also suitable for steam operation.

The velocity fuse is a product of the REGO Division of Golconda Corporation, 4201 West Peterson Avenue, Chicago, Illinois 60646. They are available from REGO and/or their distributors throughout the country.

Note: this tip has taken something of a “life of its own” since it is one of the few references to compressed air velocity fuses on the net. We do not have further information on this item.

TIP # 039 : WINTER OPERATION

Cold weather operation of Pile Hammers and Pile Extractors on compressed air frequently presents problems of ice accumulation in valve assemblies and air passage ports. Icing is a function of temperature and humidity and causes erratic equipment oper...

Read More

Tip #039: WINTER OPERATION

Cold weather operation of Pile Hammers and Pile Extractors on compressed air frequently presents problems of ice accumulation in valve assemblies and air passage ports. Icing is a function of temperature and humidity and causes erratic equipment operation. There are several remedies for this problem which will help eliminate the icing condition:

- Install on your compressor the Vulcanaire Supertherm. At 400° F air temperature, ice is nonexistent.

- In your air line oiler, dilute your lubricating oil with an equal amount of ethylene glycol.

- Install in the air line between the Lubricator and the Hammer a Tanner De-lcer Tank. The Tanner De-lcer atomizes the anti-icing chemical into the airstream to prevent Hammer icing. Tanner gas equipment is available from Tanner Systems, Inc., Sauk Rapids, Minnesota 56379.

Always remember that in subfreezing weather it is essential to preheat the Hammer Cylinder prior to commencing daily operation. This is necessary to eliminate any frozen condensate inside tile Cylinder and Valve. It is also necessary to prevent possible cracking of the Cylinder due to thermal shock.

During winter operation, it is advisable to be sure that all condensate is expelled from the Lubricator at the end of the shift so that it will not be allowed to freeze thereby plugging the oil suction line. It is also advisable to preheat the Lubricator to assure immediate lubrication when operations are commenced.

If your crane boom is hard piped part way up, it is desirable that this piping be insulated to help minimize losses in air volume due to cooling.

Note: use of these procedures may be affected by environmental regulations.

TIP # 040 : OUTBOARD BRACKET SHIMS

On all Vulcan and Super Vulcan Offshore Pile Hammers, and all Vulcan Hammers equipped for Vari-Cycle, there is an extension of the Open Steam Chest Head (see illustration) called the "Outboard Bracket." This serves not only as a guard to protect the...

Read More

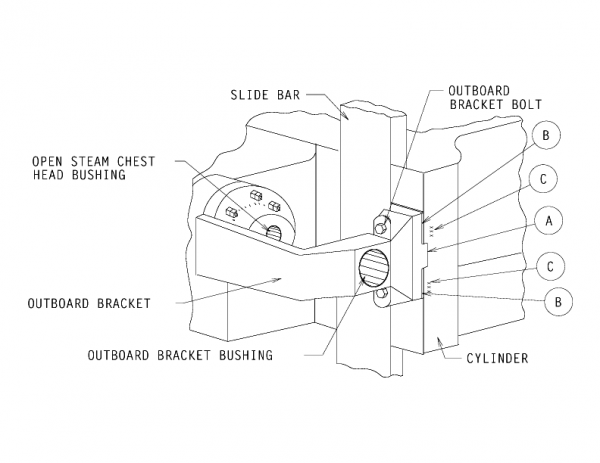

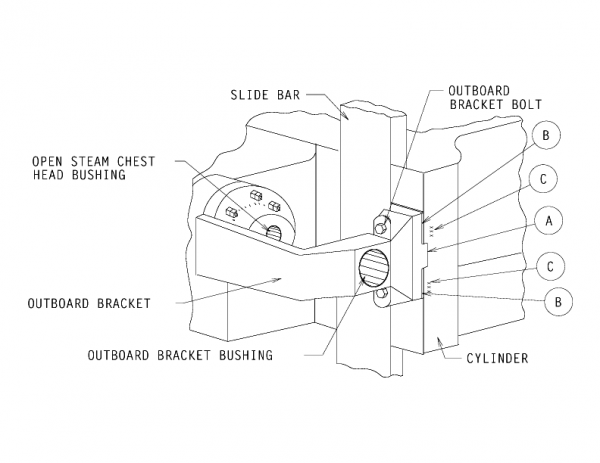

Tip #040: OUTBOARD BRACKET SHIMS

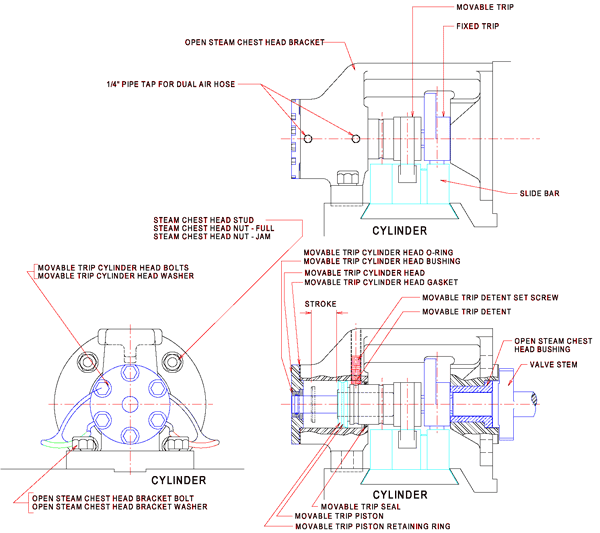

On all Vulcan and Super Vulcan Offshore Pile Hammers, and all Vulcan Hammers equipped for Vari-Cycle, there is an extension of the Open Steam Chest Head (see illustration) called the “Outboard Bracket.” This serves not only as a guard to protect the Slide Bar from damage and cables, but It also serves as an outboard bearing for the extended end of the Valve Stem.

On all Vulcan and Super Vulcan Offshore Pile Hammers, and all Vulcan Hammers equipped for Vari-Cycle, there is an extension of the Open Steam Chest Head (see illustration) called the “Outboard Bracket.” This serves not only as a guard to protect the Slide Bar from damage and cables, but It also serves as an outboard bearing for the extended end of the Valve Stem.

It is absolutely essential In the final installation that the outboard bearing be right in line with the bore of the Bushing in the Open Steam Chest Head. Due to unavoidable differences in the manufacture of the Cylinder and the Outboard Bracket, a certain amount of Selective Assembly is necessary.

Inasmuch as the foot of the Outboard Bracket is bolted to the Cylinder. it is easy to create misalignment by excessive bolting pressure. It is therefore necessary to shim the foot of the Outboard Bracket to assure alignment of the two Bushings.

The foot of the Outboard Bracket is a “tongue and groove” joint with the Cylinder (see letter A). Shim Stock (see letter B) is required as shown in the illustration. Stamped into the Cylinder Casting on either side of the “tongue and groove” joint are the thickness requirements for the Shim Stock (see letter C). DO NOT DEVIATE FROM SPECIFIED SHIM REQUIREMENTS The following information should be remembered:

- Outboard Brackets are only included on Offshore Hammers and Onshore hammers equipped with Van-Cycle from Size O8 up.

- When purchasing a new Cylinder, always include a new Outboard Bracket so that mating fit is assured.

- When removing Outboard Bracket for maintenance reasons, be sure to keep the Shim Stock for each side intact for reinstallation

- When ordering a new Outboard Bracket, new Shim Stock will be furnished in adequate quantity for installation.

TIP # 041 : VALVE FLUTTER

In "Vulcan Tip No. 3" issued some time ago, the subject of "Valve Flutter" was covered in part by various methods of control. This problem occurs in older hammers frequently and in some cases in newer hammers when operated on compressed air. In addit...

Read More

Tip #041: VALVE FLUTTER